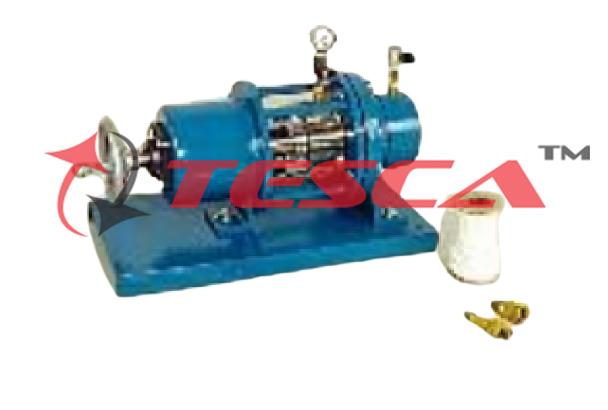

Pump Packaging Mechanical Sealing Demo

Order Code: 32130

Category: Strength of Materials Lab

Features: Formed, 7-gauge, steel baseplate with provision for bench-top mounting. Clear acrylic "backhead" and stuffing box, allowing for complete visibility of the seal area, and allowing for installation of many commercially...

SPECIFICATION

Features:

- Formed, 7-gauge, steel baseplate with provision for bench-top mounting.

- Clear acrylic "backhead" and stuffing box, allowing for complete visibility of the seal area, and allowing for installation of many commercially available mechanical seals.

- PVC, simulated impeller housing with water inlet, vent, and drain.

- Aluminum shaft assembly, incorporating stainless steel, 1-3/4" shaft sleeve.

- Aluminum spacer assembly, connecting impeller housing and power-end.

- Aluminum, simulated power-end, incorporating sleeve bearing and radial ball bearing for pump shaft support.

- Provision for attaching leak-off tubing or coolant recirculation tubing in the seal area.

- Quick-disconnect tube fittings at all fill, vent, and drain locations.

- Aluminum lantern ring.

- Aluminum packing gland.

- Acrylic replacement packing gland for mechanical seal applications.

- Handwheel, allowing for shaft rotation.

- Provision for mounting on the Tesca Electro-Mechanical Bench.

- Overall size of 225W x 500L x 250H in mm, Weight @ 25Kgs

Tesca Pump Packing/Mechanical Sealing Demonstrator is unique, a multi-use device that allows for demonstration and training related to industrial pump sealing systems.

Based on the dimensions of a standard ANSI centrifugal pump and incorporating a clear acrylic seal area, this lightweight demonstrator allows for the installation and testing of a broad variety of mechanical seals and conventional packing systems.

A PVC, representative impeller housing, leak-off taps, and provision for vents and drains, allow for the introduction of pressurized water to test seals and packing under pressure. Food coloring can be added to allow greater visibility of migration through an improperly packed stuffing box or leaking in a mechanical seal that has been installed incorrectly.

This light-weight, portable, yet realistic training demonstrator will be an excellent addition to any course relating to pump operation and maintenance.

Technical Specification:

The trainer is an industry-based heavy-duty device that allows for training in :

a. Installation of a broad range of mechanical seals used in pumps.

b. Hydraulic pressure testing of seals and packing for leaks

Impeller housing with water inlet, vent, and drain.

The following components are made of aluminum or any other-suitable durable material and shall replicate the size and shape of a standard available centrifugal pump:

a. Shaft assembly with a stainless steel shaft sleeve

b. Spacer assembly

c. Simulated power end

d. Lantern ring

e. Packing gland

The shaft of the trainer can be rotated manually.

The sealing area must be made of transparent durable material to allow visibility of the operation of the sealing system

The trainer has the following features:

a. The seal area has tubing attachments for leak-off and coolant recirculation.

b. Tube fittings at all fill. vent and drain locations can be safely and quickly disconnected.

Approx. dimensions: 225W x 500L x 250H in mm

The trainer is coated with high durability coating.

Standard Accessories:

One Set Of Tool Kit Per Trainer Includes The Following Components Or Equivalent:

a. Min Of 1 Unit Depth Scale

b. Min Of 2 Units Packing Pullers

c. Min Of' 2 Units Lantern Ring Pullers

d. Min Of 1 Unit Packing/pusher Driver

e. Min Of 1 Unit Packing Cutting Mandrel

f. Min Of 1 Unit. Inspection Mirror.

g. Min Of 1 Unit Metal Toolbox.

One Set Of Assemblies For Venting .and Filling Valve And Hose And Adapters Per Trainer

Two Sets Housing Gaskets Per Trainer

One Set Replacement Packing Gland Per Trainer

One Set Of Mechanical Seals Per Trainer:

a. Non-pusher Seal, With Acrylic Gland Adapter. Qty: 1 Unit

b. Mechanical Pusher Seal, With An Acrylic Adapter. Qty: 1 Unit

c. Single-stage Cartridge Seal. Qty: 1 Unit

Two Units Of Pressure Gauges With Connection Fittings Per Trainer.

Two Bottles Of Liquid Coloring Per Trainer

Five Spools Of 3/8 Inches In Braided Packing Per Trainer

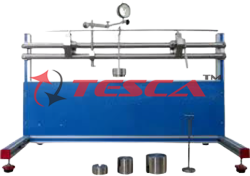

One Unit Metal Test Bench Per Trainer For Hydraulic Testing Of Leaks Consisting Of:

a. Water Pump, Capacity Minimum 6m3/hr

b. Stainless Steel Tank Of Minimum Capacity 100 Liters

c. Electric Motor 230v, 50hz, Single Phase.

Set Of Cd/dvd Consist Of 3 Part Series On Industrial Seals And Packing

91-9829132777

91-9829132777