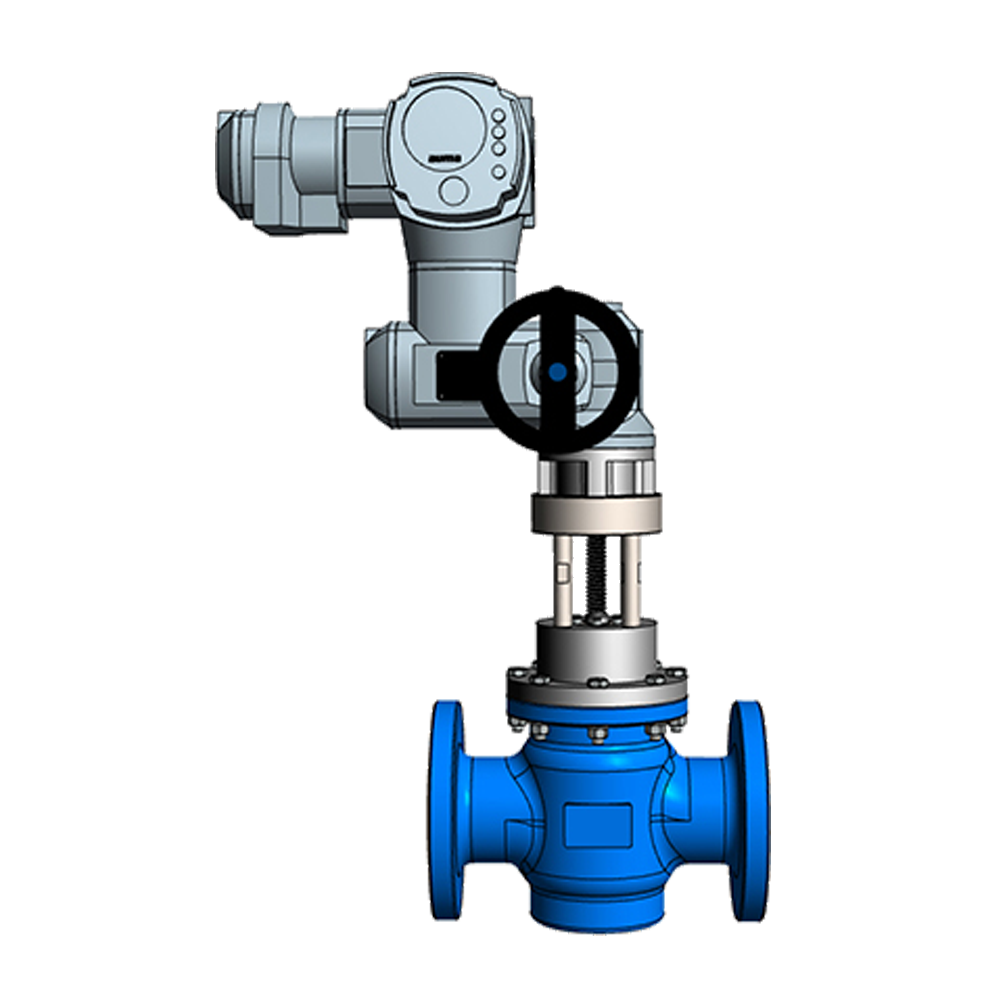

LFC™_3B Electrically Actuated Valves

Order Code: LFC™_3B

Category: Range of Low Pressure Valves

OVERVIEW The LFC™_3B Electrically actuated Isolating valves were designed to be simple and easy to operate. Due to the hydraulically balanced design and low torque requirements the valve requires a relatively small electrical actuator with n...

SPECIFICATION

OVERVIEW

The LFC™_3B Electrically actuated Isolating valves were designed to be simple and easy to operate. Due to the hydraulically balanced design and low torque requirements the valve requires a relatively small electrical actuator with no external gearbox. This feature saves capital and long term maintenance costs. Any make of electrical actuator can be fitted on the LFC™_3B electrically actuated isolation valve. The LFC™_3B electrically actuated isolation valves are generally used in pump discharge control, PLC regulated control or any other automated applications.

The LFC™_3B electrically actuated isolation valve has been developed to present a robust, simple and cost effective low pressure (up to 2.5 MPa / 363 Psi) solution to fluid handling issues in any industrial sector.

LOW OPERATING TORQUE

The LFC™_3B Electrically isolation valve is hydrostatically balanced to enable easy opening and closing at any pressure and differential conditions. It does not require the use of a gearbox or a by-pass valve to balance pressure between the inlet and outlet. The differential pressures do not affect the operating torque which results in a relatively flat torque curve allowing for the fitment of smaller actuators.

OPERATING CONDITIONS

These valves are designed to operate in systems with relatively clean media like water or other liquids with a low percentage of suspended solids and chlorides. The valve's operating pH range is 2 - 14 pH.

SIMPLICITY

The LFC™_3B valve is designed to minimize wearing parts and in effect only has one moving part called the plug. The plug is a piston that is engineered to be balanced. The balanced plug uses the inline fluid pressure to remove the influence of differential pressure on operating torque. As such, the valve operating torque is the torque required to overcome the sum of the friction forces generated between the valve seals and the sleeve plus the weight of the plug (depending on the installation con figuration). This torque requirement is not affected by inline pressure variants and as such makes the balanced valves extremely good for actuation applications. Removal of gearboxes reduces maintenance requirements and improves troubleshooting times.

LOW MAINTENANCE REQUIREMENT

All the moving parts of the LFC™_3B Electrically isolation valves are manufactured from stainless steel which increases reliability and durability. The LFC™_3B requires minimal maintenance, the majority of which, can be conducted with the valve remaining in situ.

ROBUST, RELIABLE & EFFICIENT

Due to the minimal number of moving parts to effect the fluid control, the number of potential failures are minimized.

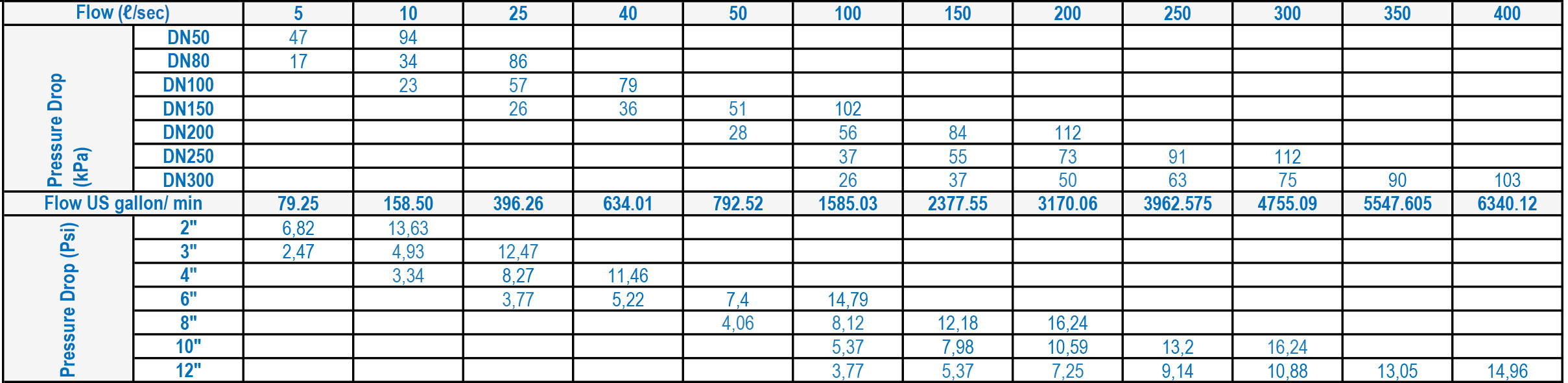

FLOW RATES

VALVE SIZING

Please consult with Hydromine for clarification of correct sizing for your requirements.

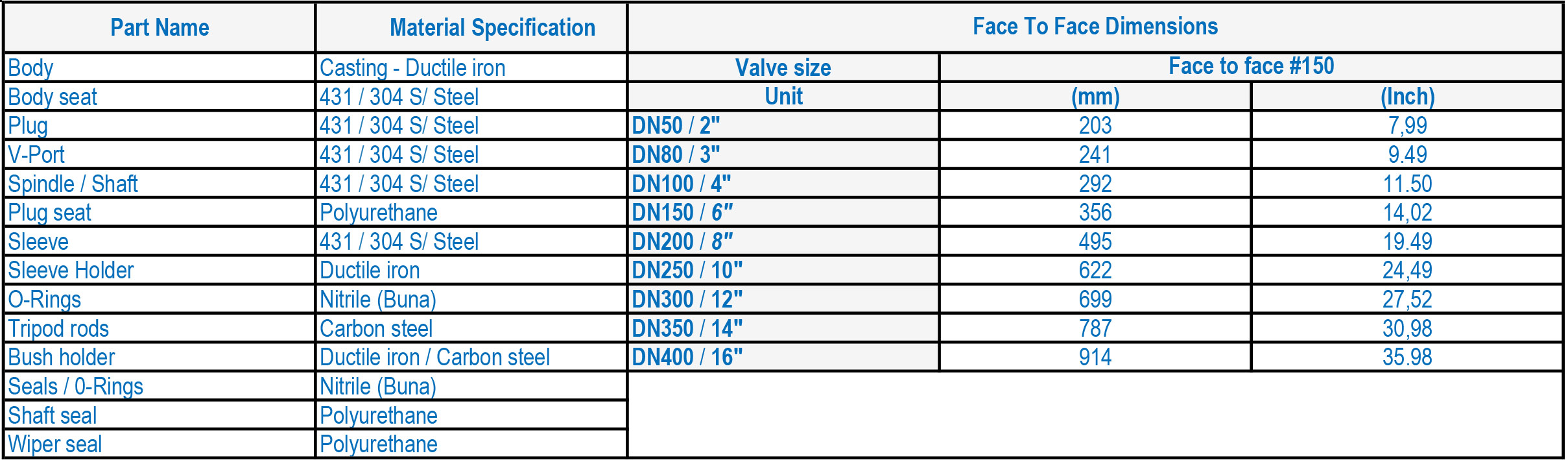

MATERIALS OF CONSTRUCTION & DIMENSIONS

DESIGN AND MANUFACTURING STANDARDS

The LFC™_3B electrically actuated isolation valve has been designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10 ANSI B16.3

ANSI B16.34 ANSI B16.37

ANSI B16.5 ANSI N278.1

Available sizes: DN50 / 2" to DN400 / 16"

Face to face dimensions to ANSI Bl6.10

Pressure rating: up to 2.5 MPa / 363Psi

Available end connections: ANSI Bl6.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN, All makes of grooved or ring joint couplings and other as per client’s requirement.

91-9829132777

91-9829132777