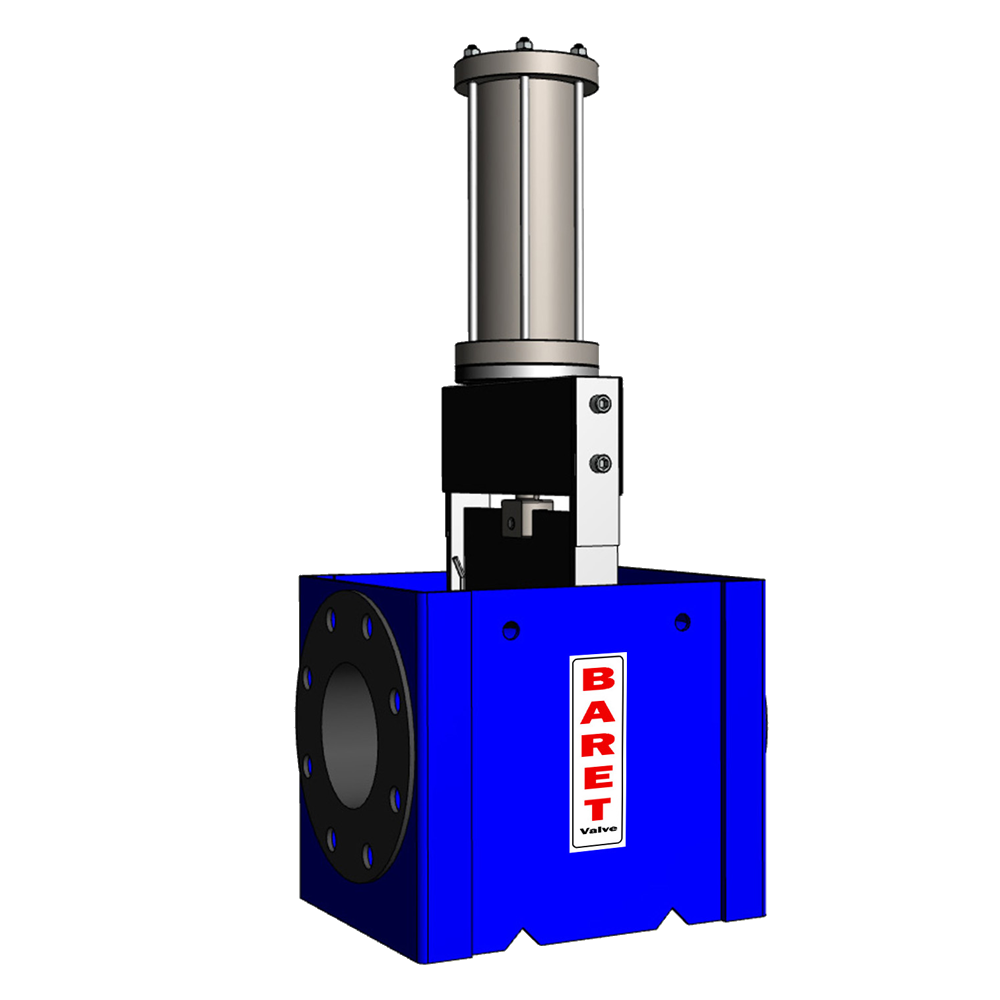

LFC™_22 Pinch Type Surge Prevention Valve (BARET Valve)

Order Code: LFC™_22

Category: Range of Pinch Valves up to PN25

OVERVIEW The LFC™_22 Pinch Type Surge Prevention System is designed to prevent water hammer or pressure surges in dirty water or slurry pumping systems. Especially in mining applications. Water hammer (or, more generally, fluid hammer) is a ...

SPECIFICATION

OVERVIEW

The LFC™_22 Pinch Type Surge Prevention System is designed to prevent water hammer or pressure surges in dirty water or slurry pumping systems. Especially in mining applications. Water hammer (or, more generally, fluid hammer) is a pressure surge or wave resulting when a fluid in motion is forced to stop or change direction suddenly (Momentum Change).

Hydromine used their tried and tested LFC™_1B high pressure surge prevention system concept and combined the technology with the tried and tested BARET Valve from Zimbabwe Valve to develop the LFC™_22 Pinch Type Surge Prevention System. It presents a robust, simple, and cost effective (up to 2.5 MPa / 363 psi) solution to abrasive liquids handling issues in any industrial sector.

Water hammer commonly occurs when a pump is stopped suddenly, and a pressure wave propagates in the pipe. It is a force that can arise in any pumping system that undergoes abrupt changes in its rate of flow. These flow changes can result from pump starts and stops, the opening and closing of valves, and column separation and closure. The piping design does have an effect upon water hammer but, we have identified the main conditions resulting in hammer.

WHEN DOES WATER HAMMER / PRESSURE SURGE OCCUR?

Water hammer will normally occur in a pumping system when one of 3 conditions occur:

1. A total power failure, causing all the running pumps to trip.

2. The emergency stop is activated on the last running pump.

3. Tripping of the last running pump.

WATER HAMMER / PRESSURE SURGE

Typically, water hammer travels at the speed of sound through its medium which can amount to 1 481 m/s (Ave 995m/s) in water. Water is only partially compressible. At ambient temperature one pound of pressure will decrease its volume by a factor of about 0.0000034. The larger the volume of water, the easier it is to see the effect of water hammer. Compression begins at the leading edge of the water column and when the additional energy it produces cannot continue on past the closed valve (Non-Return valves), a pressure or shock wave is generated which travels back upstream. The inception of this shock wave is very similar to the "echo" that is produced when a sound wave, traveling through air, strikes some barrier. When the wave hits the upstream valve, it is reflected back downstream but with a diminished intensity. This, back and forth, motion continues until friction and reflection losses cause the waves to dissipate. The speed at which a wave travels and the energy it loses during travel depends upon the density and compressibility of the medium in which it is traveling. It turns out that the density and compressibility of water make it a very good medium for shock wave generation and transmission.

SIMPLICITY

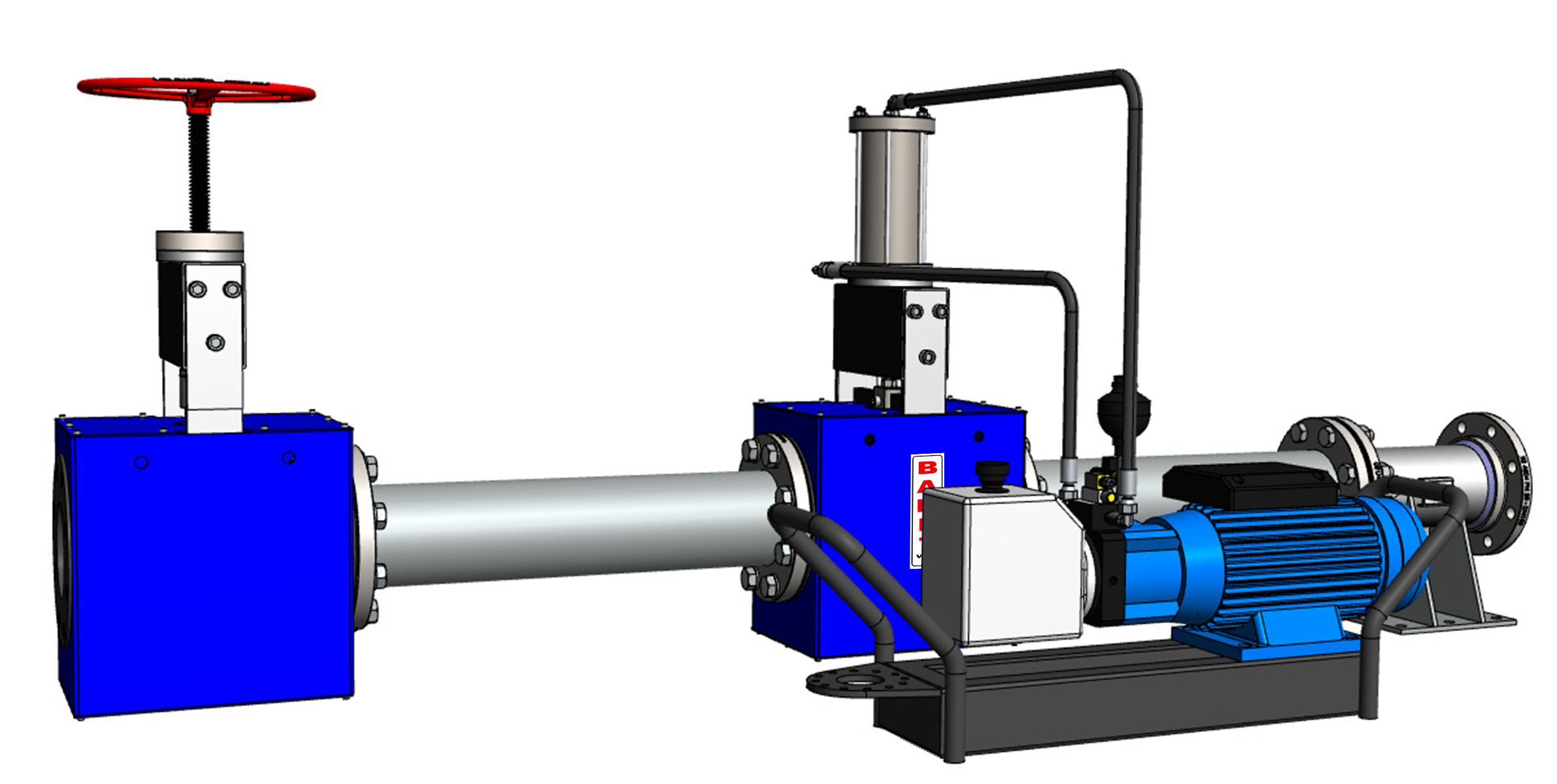

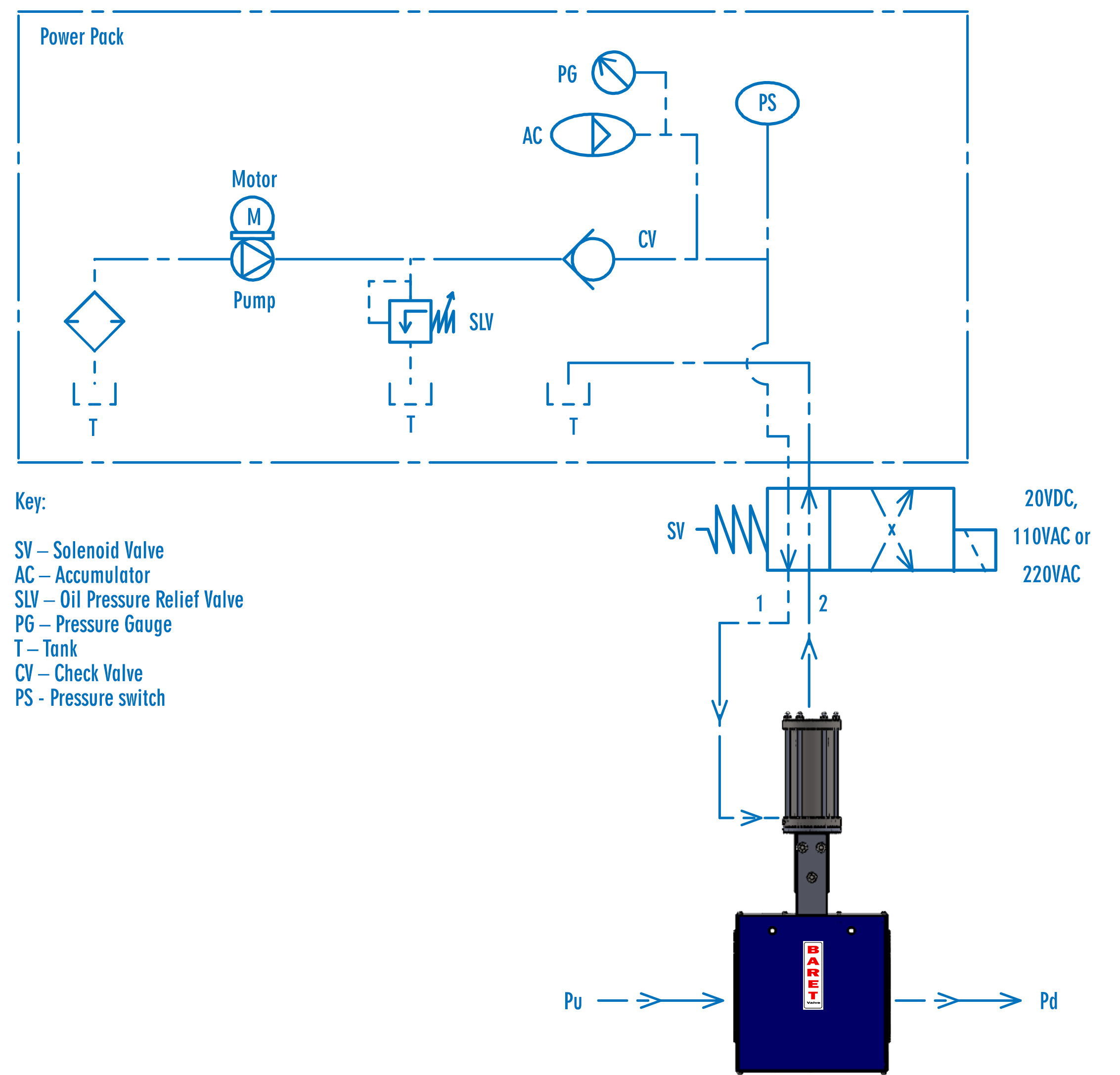

The LFC™_22 Pinch Type Surge Prevention Valve System is designed to minimize wearing parts. The LFC™_22 Pinch Type Surge prevention valve is oil hydraulically actuated using a small hydraulic power pack to actuate.

This rapid displacement of oil stored in an accumulator under pressure causes the LFC™_22 Surge Prevention valve to open extremely quickly.

LOW MAINTENANCE REQUIREMENT

All the actuator parts of the LFC™_ 22 Pinch Type Surge Prevention Valves are manufactured from stainless steel which increases reliability and durability. The LFC™_22 (BARET Valve) sleeves are relatively easy to change should it be worn or ruptured. Lifting holes makes handling and installation earlier.

OPERATING CONDITIONS

The BARET Valve have a long history, being used in applications with slurries, pulps and a wide range of aggressive fluids. The natural rubber sleeve formulation gives good wearing characteristics and long work life.

THE EFFECTS OF WATER HAMMER / PRESSURE SURGE

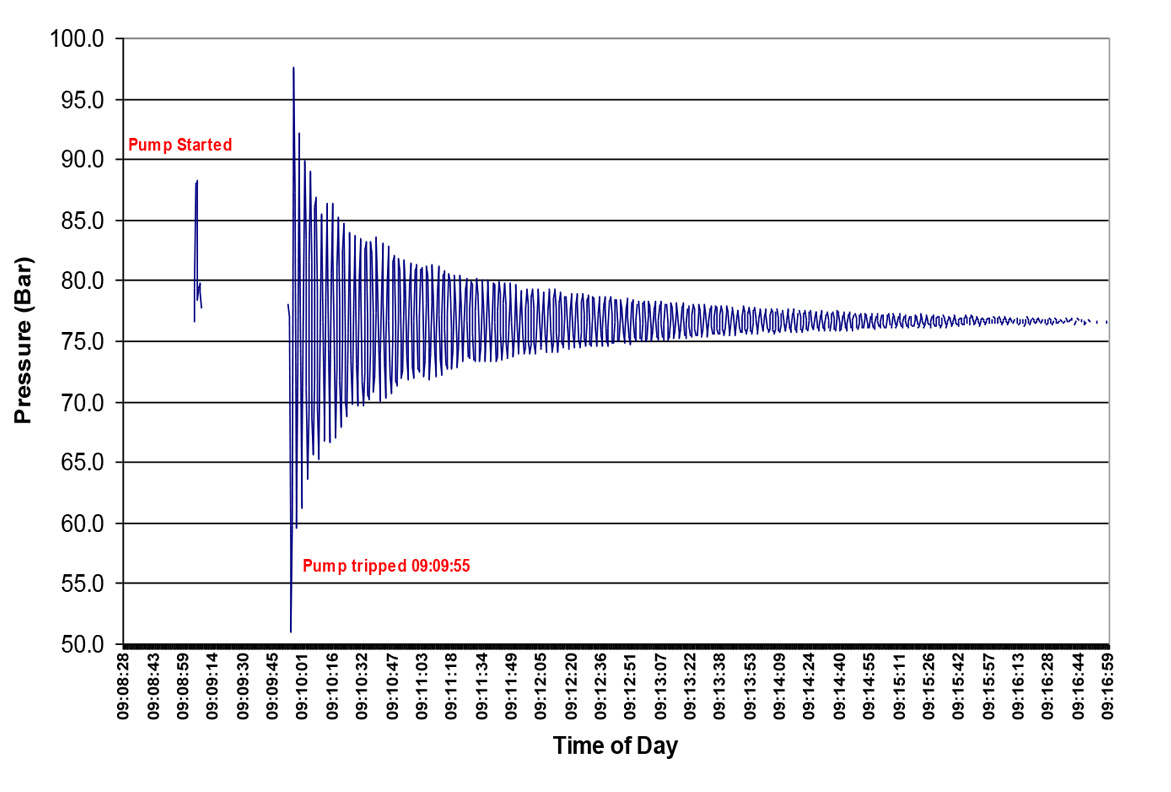

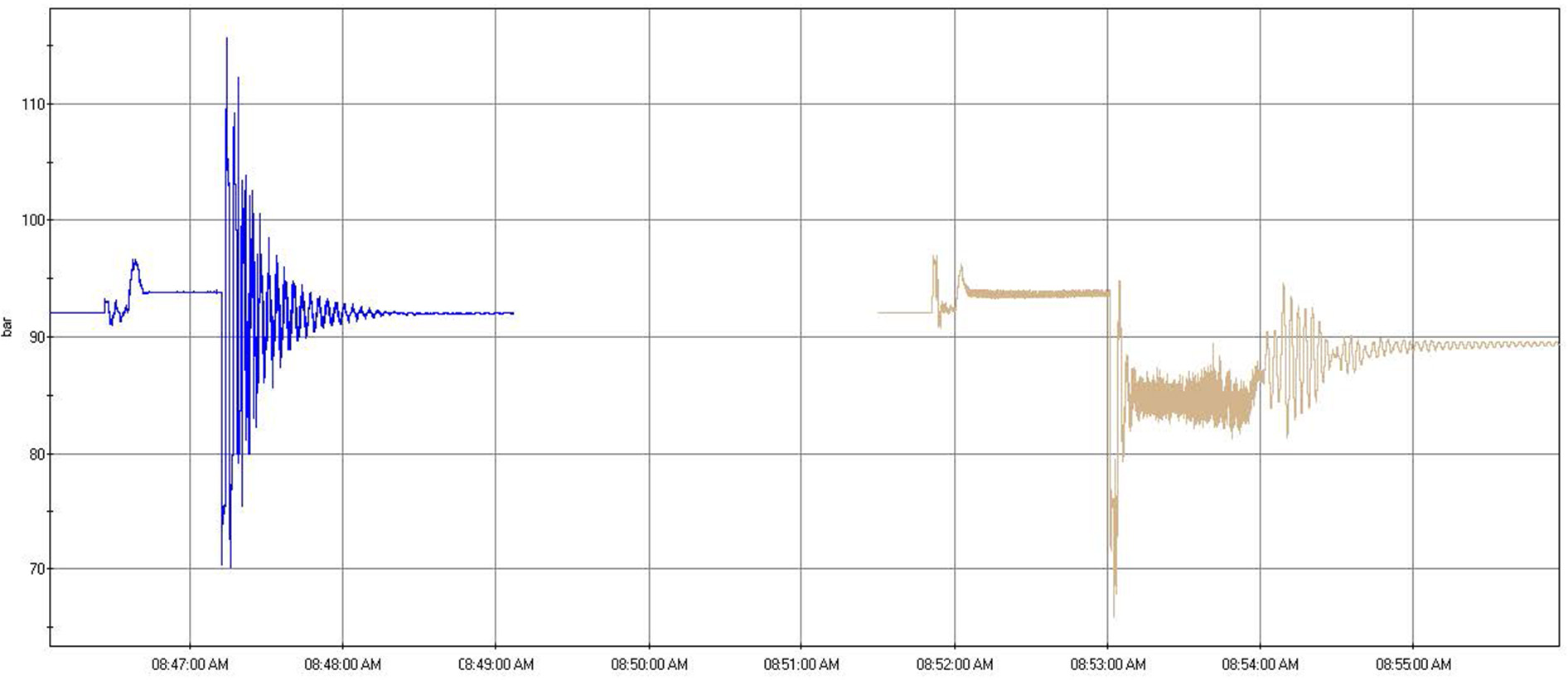

The graph shows the effects of water hammer on a pump station in an Mine, with an underground pump station of 770m static head when 1 pump tripped.

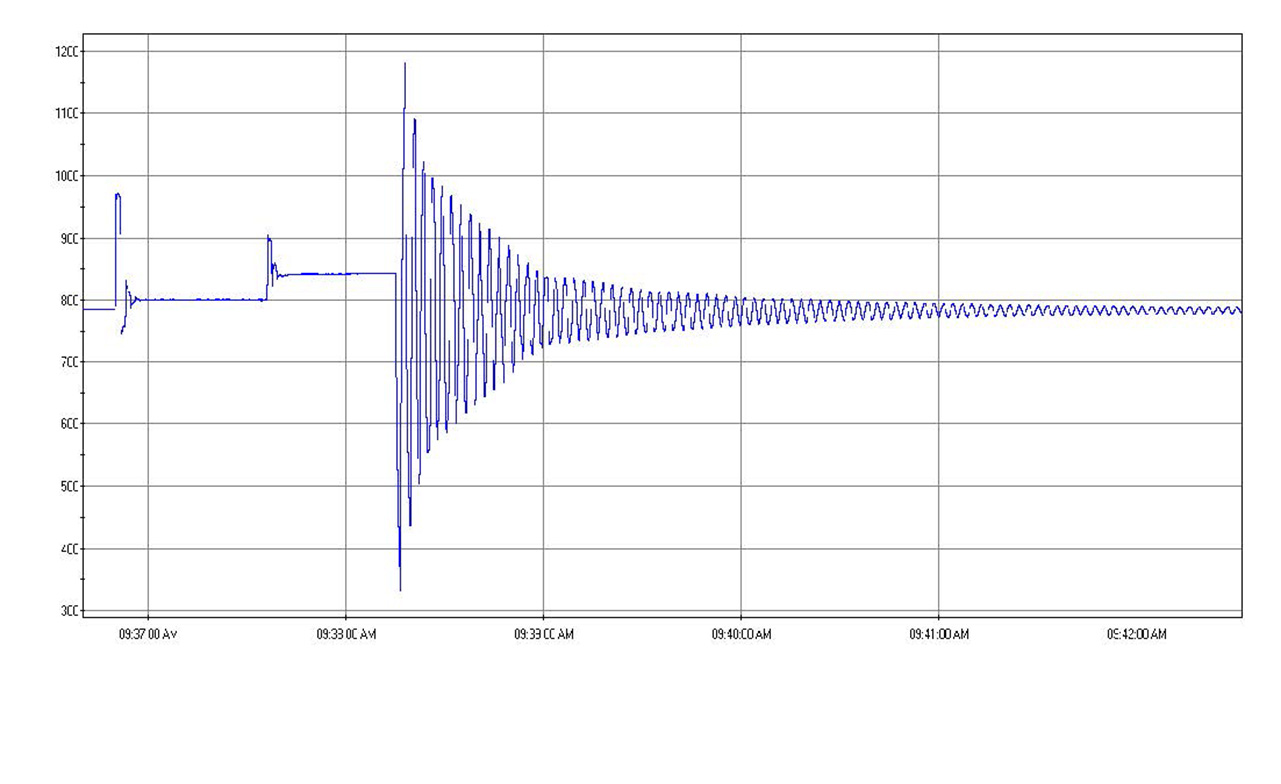

The graph shows the effects of water hammer in a Mine pump station, with an under ground pump station of 786m m static head when 2 pumps tripped.

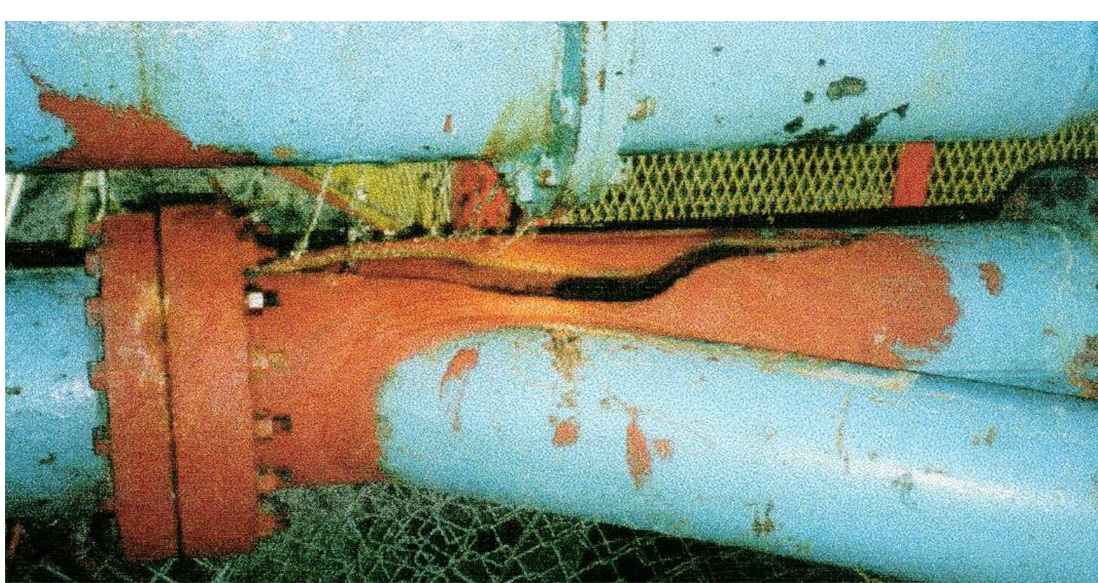

This is the result of water hammer in a Mine pump station, with an underground pump station of 750m static head after 1 pump tripped, due to a total power failure.

HOW DOES IT WORK?

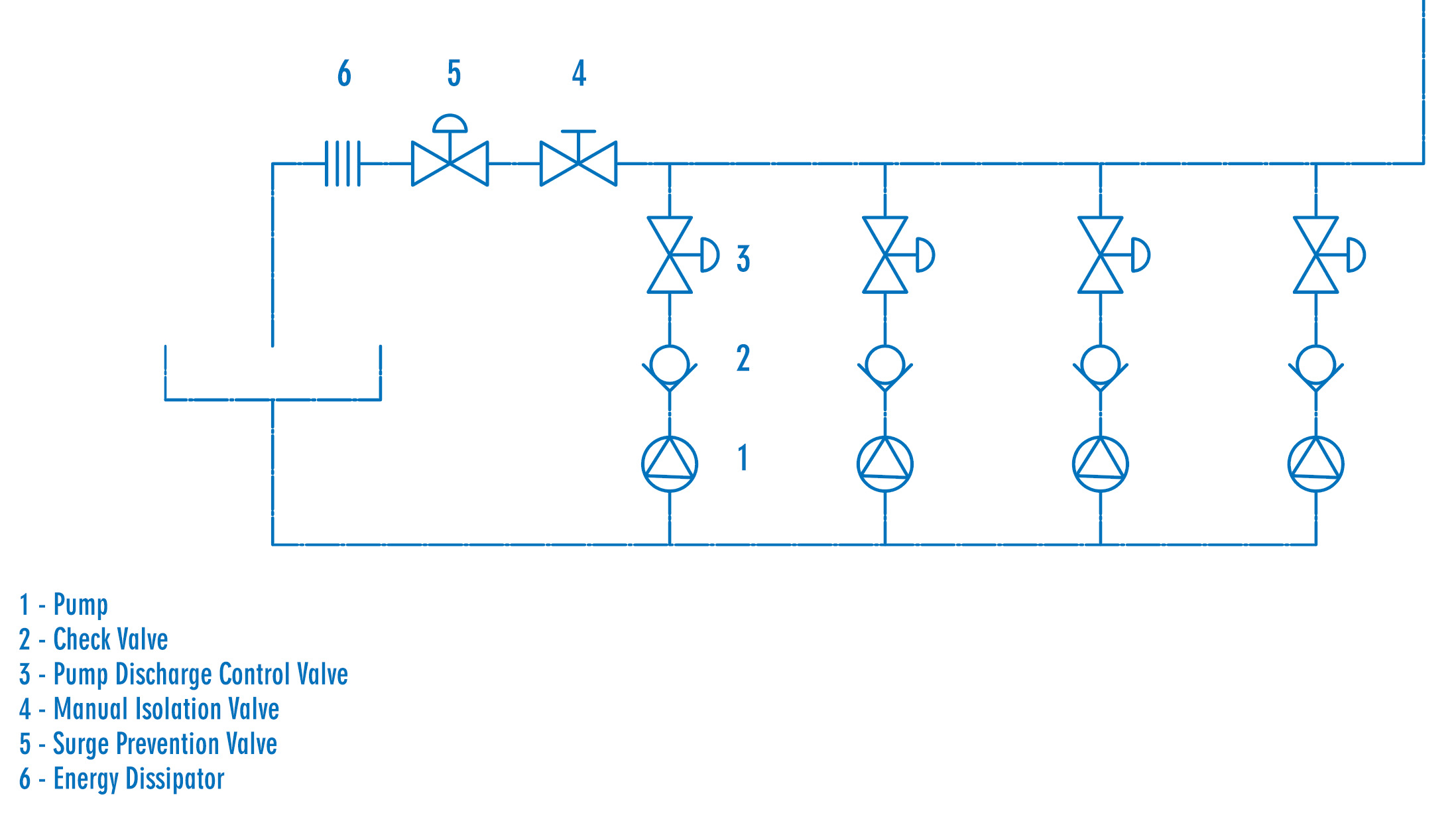

The LFC™_22 Pinch Type Surge Prevention Valve opens rapidly when there is an abrupt stop of the last running pump, or a total power failure during dewatering. At that stage the flow is still moving away from the pump station, but as soon as it loses its driving force and energy it will start returning towards the pump station. Due to the open LFC™_22 Pinch Type Surge prevention valve, the returning column of water is met with an open orifice and an exit point for any energy build up.

The flow moves through the surge prevention valve and energy dissipator installed after the valve. After keeping the LFC™_22 Pinch Type Surge Prevention Valve open for +/- 10 seconds, the surge prevention valve starts closing in a controlled manner to prevent any surging. The function of the energy dissipator is to discharge the flow at safe pressure and a set flow to atmosphere into the suction dam or drain. The graph on the left shows the effects of water hammer on an underground pump station with 920m static head when 1 pump tripped. The graph on the right shows the result of using the LFC™_1B surge prevention valve system in the same pump station, when 1 pump tripped. It clearly demonstrates the effectiveness of the solution and shows that no water hammer was experienced.

LFC™_22 PINCH TYPE SURGE PREVENTION SYSTEM WITH COMPACT OIL HYDRAULIC POWER PACK

TYPICAL PUMP STATION WITH SURGE PREVENTION SYSTEM

SURGE PREVENTION SYSTEM

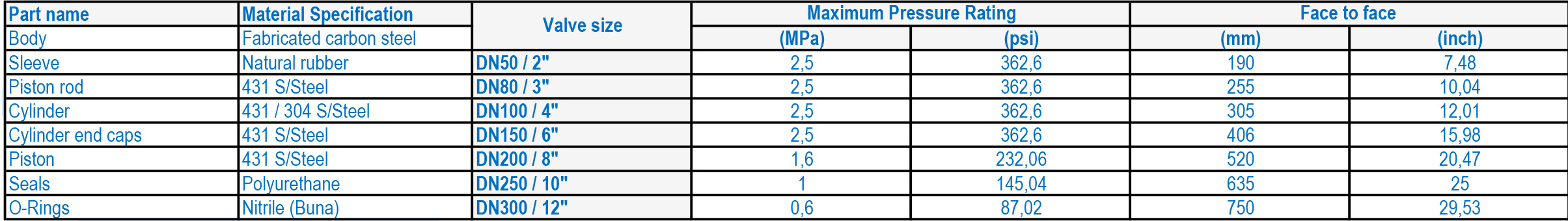

MATERIALS OF CONSTRUCTION & DIMENSIONS

DESIGN STANDARDS

The LFC™_22 Pinch Type Surge Prevention Valve (BARET Valve) has been designed in accordance with various international standards.

Available sizes: DN50 / 2" to DN300 / 12"

Pressure rating: up to 2.5 MPa / 363psi

Available end connections: ANSI Bl6.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN and other as per client’s requirement.

MANUFACTURING STANDARDS

The BARET Valve has been manufactured to an ISO 9002 Quality Assurance System since 1994

91-9829132777

91-9829132777