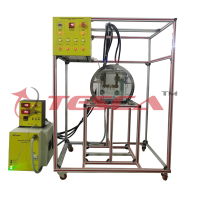

Heat Transfer by Convection & Radiation Module

Order Code: 32358

Category: Thermodynamics Lab

Features Heat transport between heating element and vessel wall by convection and radiation Software for data acquisition Under real conditions, the heat transport between two objects is normally substance-bound, i....

SPECIFICATION

Features

Heat transport between heating element and vessel wall by convection and radiation

Software for data acquisition

Under real conditions, the heat transport between two objects is normally substance-bound, i.e. convection and/or heat conduction, and not substance-bound, i.e. radiation, at the same time. Determining the individual heat quantities of one type of transfer is difficult.

Tesca Heat Transfer by Convection & Radiation trainer enables users to match the individual heat quantities to the corresponding type of transfer. The core element is a metal cylinder in a pressure vessel. A temperature-controlled heating element is located at the centre of the cylinder. Sensors capture the wall temperature of the cylinder, the heating temperature and the heating power. This metal cylinder is used to examine the heat transfer between the heating element and the vessel wall.

The pressure vessel can be put under vacuum or positive gauge pressure. In the vacuum, heat is transported primarily by radiation. If the vessel is filled with gas and is under positive gauge pressure, heat is also transferred by convection. It is possible to compare the heat transfer in different gases. In addition to air, nitrogen, helium, carbon dioxide or other gases are also suitable.

A rotary vane pump generates negative pressures down to approx. 0,02mbar. Positive gauge pressures up to approx. 1bar can be realized with compressed air. Two pressure sensors with suitable measuring ranges are available for the pressure measurement: the negative pressure is captured with a Pirani sensor; a piezo resistive sensor is used for experiments with a filled cylinder.

The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB, where they can be analyzed with the software.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications

Heat transfer between heating element and vessel wall by convection and radiation

Operation with various gases possible

Experiments in vacuum or at a slight positive gauge pressure

Electrically heated metal cylinder in the pressure vessel as experimental vessel

Temperature-controlled heating element

Vacuum generation with rotary vane pump

Instrumentation: 1 temperature sensor at the heater, 1 temperature sensor at the vessel wall, 1 power sensor at the heating element, 1 Pirani pressure sensor, 1 piezo-resistive pressure sensor

Digital displays for temperature, pressure and heating power

Software for data acquisition via USB under Windows Vista or Windows 7

Technical Specifications

Heating element

Output: 20w

Radiation Surface Area: Approx. 61cm²

Pump for vacuum generation

Power Consumption: 370w

Nominal Suction Capacity: 5m³/h

Final Pressure With Gas Ballast: 20*10 3mbar

Final Pressure Without Gas Ballast: 5*10-3mbar

Measuring ranges

Negative pressure: 0,5*10-3...1000mbar

Pressure: -1...1,5bar rel.

Temperature: 2x 0...200°C

91-9829132777

91-9829132777