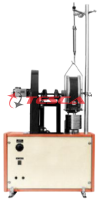

Heat Exchanger – Mixed Heat Flow

Order Code: 32284

Category: Thermodynamics Lab

Mixed Heat Flow Heat Exchanger is an important subject in Engineering and Technology. Tesca Mixed Heat Flow Heat Exchangers are process equipment in which cold and hot fluids flow and heat is exchanged between a hot fluid to a col...

SPECIFICATION

Mixed Heat Flow Heat Exchanger is an important subject in Engineering and Technology. Tesca Mixed Heat Flow Heat Exchangers are process equipment in which cold and hot fluids flow and heat is exchanged between a hot fluid to a cold luid. Mixed Heat Flow Heat Exchanger have several applications in industries and proper understanding of the heat transfer phenomena in heat exchangers is essential to solve any research, design and development problem involving heat flow. Heat is transmitted basically by conduction and convection in heat exchanger. Various types of heat exchangers are used in practice depending upon several aspects such as the required heat transfer rate, availability of space, pressure drop and cost of the equipment. It is essential to demonstrate the working and understand the performance of various types of heat exchangers.

Study of Mixed Heat Flow Heat Exchanger is of interest to the students of all branches of Engineering and Technology including Mechanical, Chemical, Automobile and Aerospace Engineering.

The mixed flow heat exchanger is designed enable student to study:

The heat transfer coefficient from tube wall to shell side within a tube bundle.

It also enables student to determine the relation of Nusselt’s and Reynold numbers by varying the flow rate of air.

The Mixed flow heat exchanger is interchangeable with the heat transfer bench’s test module. It utilizes the same power source and standard interchangeable sensor connection for easy setup.

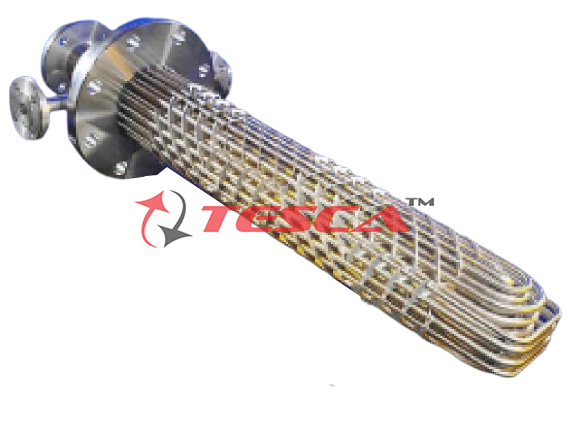

The heat exchanger unit consists of 100mm diameter OD acrylic tube with flow baffles within a tube bundle, to increase the heat transfer capacity. The baffle directs the air flow so that a mixture of cross flow and parallel flow condition prevails. The number of baffle plates and the spacing can be changed to conduct various conditions of the heat exchanger design.

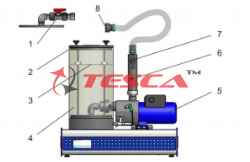

An orifice plate is installed at the heat exchanger inlet duct, to enable user to measure the air flow. Pressure drop tapping at the tube bundle allows the measurement on the inclined manometer.

The bundle tube consists of empty bundle tube with a single heated tube insert in the center of the tube bundle. A K-type thermocouple sensor is inserted in the center of tube bundle.

Optionally following can be supplied on request

1. Computer based data acquisition unit.

2. Mixed Heat Flow Heat Exchanger type having any other specific user requirements..

Instruction/Training Manuals

The manual describing the theoretical and practical aspects of the apparatus, operation and maintenance will be supplied with the equipment.

Services required

1. Single phase mains electrical supply: 220-240 V, 50 Hz.

2. Water supply.

Overall dimensions:

Length: 2m, Width: 1m, Height: 2m.

91-9829132777

91-9829132777