Gas Absorption Desorption Column

Order Code: 32323

Category: Thermodynamics Lab

Tesca Gas Absorption Desorption Column is a widely used in unit operations of chemical engineering. Gas absorption and desorption unit is a floor mounted bench scale system designed to demonstrate the principles of gas absorption and desorption for s...

SPECIFICATION

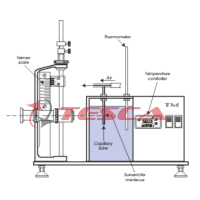

Tesca Gas Absorption Desorption Column is a widely used in unit operations of chemical engineering. Gas absorption and desorption unit is a floor mounted bench scale system designed to demonstrate the principles of gas absorption and desorption for student to investigate the principles of packed tower absorption processes and hydrodynamics as well as provide practical training in the Absorption and desorption plant. The first absorption column is designed to absorb CO2 from an air/CO2 mixture into water flowing down the column. Stainless steel tank and pump is provided to deliver fresh water supply to the top of the first column. A Mixture of Air and CO2 is fed to bottom of the column for the absorption process. This column act as a gas absorber packed with rasching rings.

Additional types of packing such as Berl saddies or spheres can be supplied. This packing is to be filled into the gas absorption column. The column is made up by two 100mm diameter borosilicate glass tubing with a total length of 1200 mm. Second column of exact dimensions is designed to adsorb CO2 from the water product from the first column into supplied air.

The product filled into the stainless steel product tank from the first experiment is delivered to the top of the second column via the second stainless steel pump. Fresh air is drawn into the bottom of the second column to remove CO2 from the liquid. A heater with temperature controller is fitted into the product tank to heat the product to saturated line for the ease of CO2 release. Additional solvent can also be added to the product to enhance the absorption process via the filling port.

The system consists of an air supply from from the compressor and a supply of pure carbon dioxide for a high pressure CO2 tank. Both of the bas streams have its own the flow meter to determine their volumetric flow rate.

There are two liquid (water) flow system using centrifugal pumps and a flow meter to determine the flow rates.

The liquid and gas flow direction is constructed such that the gas flows in coutercurrent to the liquid. This unit has 4 U-Tube manometers to determine the pressure drop across the absorpber and deabsorber units.

A stainless steel water tank is provided to supply the water into absorber. The liquid discharged from the column is to be collected to a stainless steel collecting tank to be fed to the absorber. The final product after absorption is collected at the third stainless steel tank.

Four CO2 sensors with digital display are provided to measure the CO2 Concentration before and after absorption and desorption process in gas stream. While, a gas analyzer or gas chromatograph can be used to measure gas concentration in liquid stream (or sample will be collected into special container then measure with analyzer). A pressure regulator is provided to regulate the gas stream pressure supplied to the column

Technical Specifications

Stainless steel feed tank capacity : 60 L

Stainless steel collecting tank capacity : 60 L

Stainless steel production tank capacity : 60 L

Absorption Column: Diameter of column : 80 mm; Total length of column : 1200 mm

Adsorption Column: Diameter of column : 80 mm; Total length of column : 600 mm Ÿ Type of packing (gas absorption) : Berl saddle (1/2”) or Raschig ring (10 X 10 mm) Ÿ Compressor capacity : 2 hp with 1400 rpm

Compressor tank capacity : 100 L

Centrifugal pump X 2 units : Stainless steel impeller 0.75 kW

Maximum pump delivery : 50 L/min

Air flow meters X 2 units : Range 20.0 – 180.0 L/min

Gas flow meters X 2 units : Range 1.0 – 22.0 L/min

Water flow meters X 2 units : Range 1.0 – 10.0 L/min

U-Tube manometers : Acrylic with water proof indicator

CO2 sensors X 4 units : 0 – 50% with digital display

Air regulator : Adjustable, 0 – 10 bar

Pressure gauge: 0 – 10 bar

Experimental Capabilities

1. Understanding of gas absorption and desorption working principles.

2. Study of the basic principles of the absorption of a gas into a liquid using packed column. Study of basic principles of gas desorption of liquid into air using a packed column. Determine the heating effects on desorption rate and efficiency.

3. Determine the affects of adding extracting solvent to desorption efficiency.

4. Study of relationship between water and air flow rate changes and their effect on pressure drop of an absorption and desorption.

5. Study of affect of air flow rate on flooding point in an absorption and desorption column.

6. Study the effect of water flow rate on flooding point in an absorption and desorption column.

7. Determination of absorption and desorption column flooding point and loading point

8. Study the characterization of different gas absorbers

9. Absorption of CO2 into water

10. Desorption of CO2 in heated water to air

11. Effect of water flow rate on absorption and desorption process

12. Absorption of CO2 into aqueous caustic solution

13. Determination of the mass transfer coefficients

14. Production of mass balances for a packed absorption column.

Required Services

Electric Supply 230 V AC, Single Phase, 50 Hz.

Floor Space: 4 m x 2 m

91-9829132777

91-9829132777