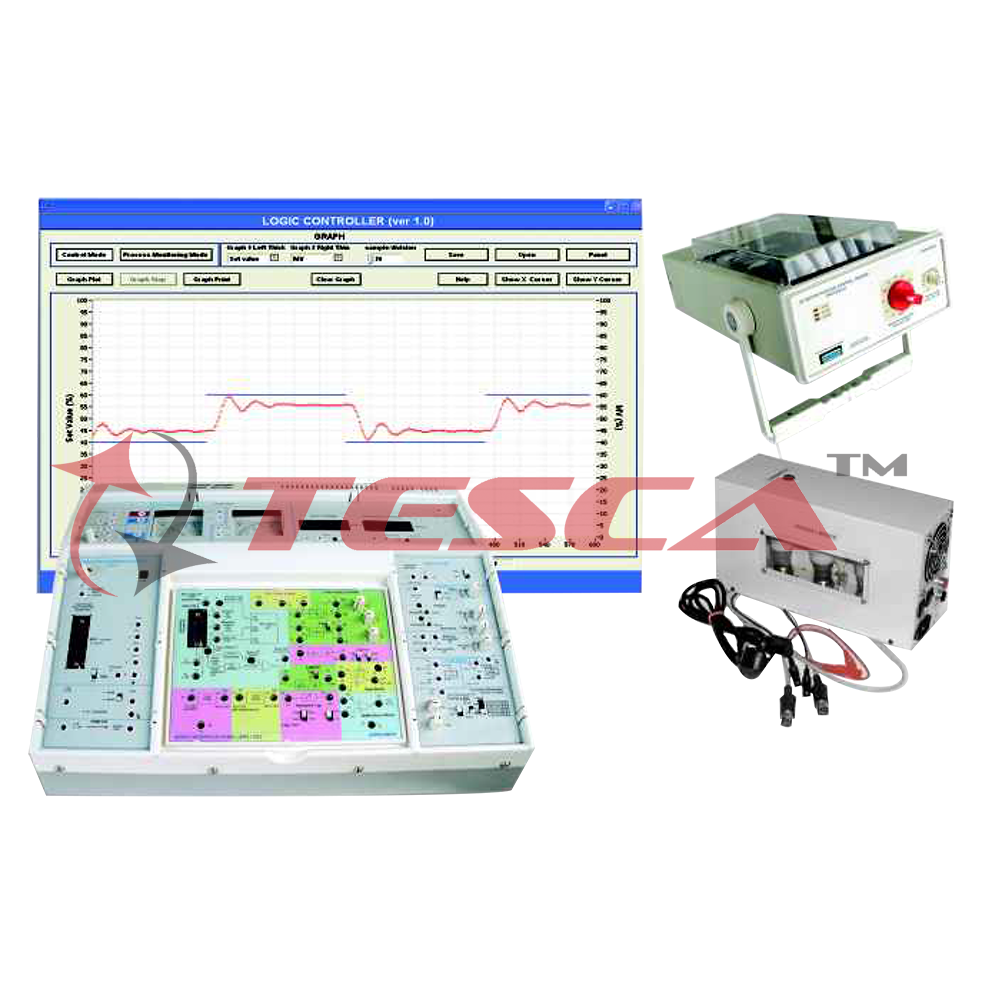

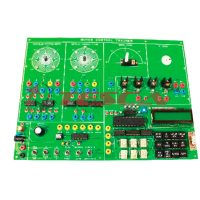

Fuzzy Logic Trainer

Order Code: 52396

Category: Instrumentation Trainers

Salient Features Labview* based Fuzzy Logic Controller. Facility to monitor behavior of the controller output (Un) & process variable (MV) either on PC screen or on CRO. Settable time constants. Graph printing facility for laboratory jo...

SPECIFICATION

Salient Features

- Labview* based Fuzzy Logic Controller.

- Facility to monitor behavior of the controller output (Un) & process variable (MV) either on PC screen or on CRO. Settable time constants.

- Graph printing facility for laboratory journal entries.

- Can learn about different processes using simulated building blocks as well as real life processes using replaceable experiment panels/processes and

- built in sqr. / trig. / sin, Function Generator as disturbance.

- Aesthetically designed injection molded electronic desk (master unit) carrying useful experiment resources like Power supplies, DPMs, Computer

- Interface, Analog PID controller with central slot to hold various replaceable experiment panels / processes.

- Connection through sturdy 4mm Banana sockets & Patch cords.

- Useful for Post Graduate projects and research purpose.

- User Manual provided with each unit.

Specification of Master Unit (MU)

- Built in Power Supply : DC supply 12V, 500mA. 1Phase sine reference for cosine firing 30Vpp. max., 17V DC, 500 mA unregulated for driving pulse X'mer, Variable DC power supply : 7 to 14V/3A.

- Display :

- DPM-2Nos., for Temp upto 100 C/500 C

- Analog Meter - 2Nos.

- Centre zero for display of process error ( 9V)

- For MV/SP (0-2.5V)

Operating voltage : Switch selectable 220-240Vac, 10%, 50Hz, 75VA.

Mechanical Dimensions:

- Main Unit : 460mm(W),160mm(H),350mm(D)

- Panel : 215mm(W),165mm(H),400mm(D),

- Net Weight Main Unit : 6.5kg.Grossweight:8.5kg.

- Net Weight Panel : 700gm.approx.

PC (P4/XP/WIN7) Software (Labview*) based Fuzzy Controller (PC not in scope of supply) *Labview is trademark of NI.

A] Fuzzy software Controller : Elegantly designed GUI of realistic fuzzy controller with bar-chart, numeric display for controller output, set point & measurable variable in % with parameter like set value Rn (0-99.9), Sampling Time Ts (0.1- 99.9), Error (0.1-99.9), Error dot (0.1-999), Fuzzy output Upper Limit Uh (0-99.9) & Lower Limit UI (0-99.9), Facility to set units for output viz. Percentage (%), °C, RPM, Voltage (V), mm, LPH, Kg/cm2. • Facility to set inbuilt FG (Square/Triangle/Sine) as set Point.

- Process Monitoring Mode : Drawing graphs of analog data presented at CH 0 & CH1 of computer Interface. Cursors for X & Y axis for measurement & online graphs savings for reproduction.

- Fuzzification Mode : Fuzzy controller based on linguistic rules & rule matrix (knowledge base), Calculation of N,Z,P, and membership function.

- Defuzzyfier : Calculation of strength of LH, MH, HH & crisp output weighted average.

- B] Computer Interface Adapter / CIA : Optoisolated Adaptor to prevent damage to PC parallel port (25 pin LPT) due to wrong connections. Interfaces through 25 pin M to F cable 1 mtr Length, 4 ADC channels: 0 to 2.5V full scale, 1DAC channels: O/p 2.5 VFS.

- USB converter to interface 25 pin D connector on CIP panel to USB using microcontroller module enclosed in 25 pin D shell using Type A to mini B cable.

Modular experiment panels offered :

Select as per table below.

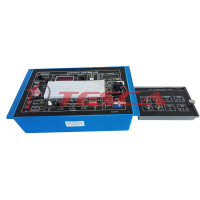

1] Servo Interface Panel (Provided with 36 banana tags.)

- Functional blocks for Lag (2 Nos.), Integrator (2 Nos.), Transport Lag (1 No.), Gain (1 No.), Buffer/error block (1 No.) for constructing simulated Type 0,1,2,3 & 1st, 2nd, 3rd Order processes to work under fuzzy control.

- Fast (10mS) & Slow (1sec) mode selection for all processes to observe response on either CRO or PC using CIA.

- Level shifters (2 Nos.) 0-2.5V to ±9V to match voltage levels of PC (2.5V).

- Control Interface circuit for AC & DC servo motor, signal conditioning circuit for speed sensor to O/P 0-2.5VDC (2500RPM) with speed direction.

2] Thyristor Actuator Panel (Provided with 13 banana tags)

- Thyristor bridge based 0-200V/3A cosine firing circuits, I/P 0 to 2.5Vdc. Supports signal conditioning of RTD (PT100), Thermocouple K type & Photodiode output 0-2.5Vdc (FS).

- Facilitates closed loop control experiments based on temperature, light intensity, speed measurement using built in P/PI controller as well as external Analog /Digital PID/Fuzzy controller.

91-9829132777

91-9829132777