Fluid Mechanics Experiment Plant

Order Code: 32094

Category: Fluid Mechanics Lab

Features: 1. Large scale to ensure realistic measurement results1 2. Operating behavior of centrifugal pumps 1 3. Pressure losses in piping elements 1 4. Kv-value determination of control valves 1 5. Flow rate and pressure control Tesca Flu...

SPECIFICATION

Features:

1. Large scale to ensure realistic measurement results1

2. Operating behavior of centrifugal pumps 1

3. Pressure losses in piping elements 1

4. Kv-value determination of control valves 1

5. Flow rate and pressure control

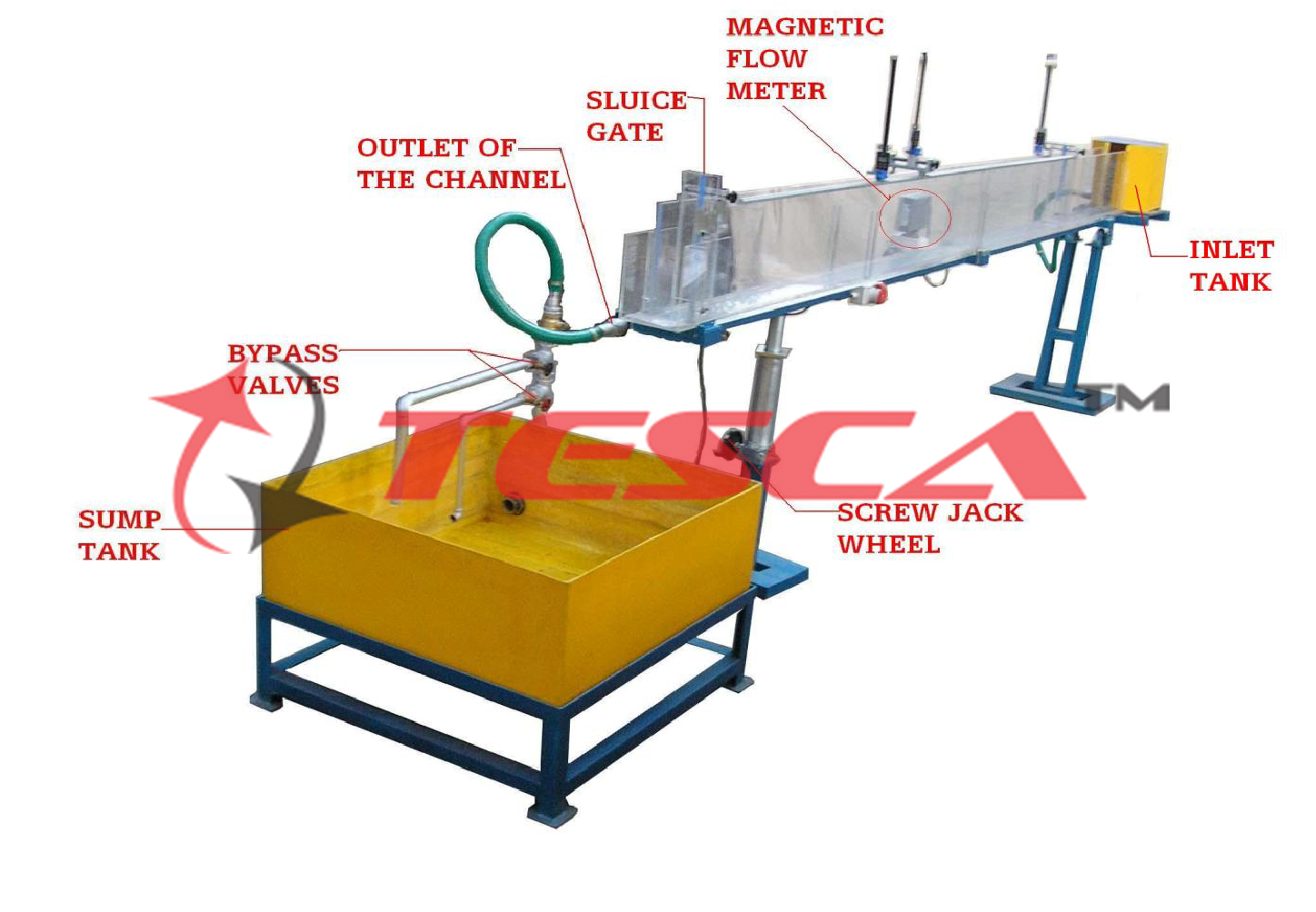

Tesca Fluid Mechanics Experimental Plant allows precise investigations of different fluidic problems. The large scale of the experimental plant and the use of industrial components deliver results close to reality. The dimensions of the experimental plant allow sufficient inlet and outlet sections for the flow formation. 32094 consists of several assemblies: a pump station with two differently sized centrifugal pumps, an intake tank, two measuring sections - each of five-meter length - one with a nominal diameter of 50mm (DN50), the other one with 25mm nominal diameter (DN25), and a control room consisting of a control console and data acquisition. Optionally the experimental plant may be operated with an additional tank on a lower level for higher suction heads. The complex system may be adjusted in a flexible way to the local facilities.

Many interchangeable piping elements allow an extensive experimental range. Using the measuring section DN50, the Kv values of different control valves can be determined conforming to standards, e.g. an electro- pneumatic control valve. A transparent pipe section with ink injection allows observing the flow in the wake of a fitting or a valve. To measure pipe resistances, pipe sections with different surface roughness are inserted in the measuring section DN25.

A pressure-controlled system controls the system pressure, the flow rate is controlled by a flow controller, and the speed of the pumps. The pumps are operated by the control console. Thus the mapping of pump characteristics is comfortably done.

The experimental plant is equipped with numerous sensors for pressure, flow rate, temperature, speed, and torque. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included.

The well-structured instructional material sets out the fundamentals and provides a step-by- step guide through the experiments.

Specifications:

Experimental Plant In Laboratory Scale

2 Measuring Sections, Each Of 5m Length

2 Centrifugal Pumps Including Electrical And Mechanical Measurement, Variable Speed Via Frequency Converter

Measuring Location Dn50 Conforming To Standards To Determine Kv-values In Control Valves

Interchangeable Piping Elements

Flow Controlled System

Separate Control Station With The Control Console And Data Acquisition

Electronic Measurement And Digital Display Of All Important Measured Values At The Control Console

Differential Pressure Control At The Determination Of Kv-value

Software For Data Acquisition Via Usb Under Windows Vista Or Windows 7

1. Pump 32/160; 2. Pump 40/250; 3. Control Console; 4. Measuring Location for Control Valves; 5. Measuring section DN 50; 6. Measuring section DN20/25; 7. Upper intake tank.

Technical Specifications:

Pipe system

Nominal diameters: DN25, DN50, DN80, DN100

Pressure stage: PN10

Intake tank: 500L (optional tank 1200L)

Control valves: 1x Kvs10, 2xKvs40, 1xKvs100

Pumps, speed: 300...3000min-1

- Norm pump 32/160, 20m³/h, 34,7m, 4kW

- Norm pump 40/250, 40m³/h, 66,5m, 11kW Pipe sections

1: length: 3m, smooth/rough, DN25/DN20

2: length: 3m, smooth, DN50

3 : l e n g t h : 1 , 2 m , 1 0 m e a s u r i n g connections, transparent, DN50

Measuring ranges

pressure: 8x 10bar, 2x -1...0,6bar

Differential pressure: 2x 0...1,6bar

- Flow rate: 1x 0...50m³/h, 1x 0...100m³/h

Orifice plate f low meter: DN 25 , 0...600mbar

List of Experiments:

1. Experiments With Pumps, Valves And Fittings, And Pipe Sections

2. Operating Behavior Of Centrifugal Pumps In Individual Or Parallel Operation

3. A Measurement Of The Npsh Value Of Pumps

4. Pressure Losses In Pipe Sections With Different Surface Roughness

5. Pressure Losses In Pipe Fittings

6. Kv-value Determination Of Control Valves And Fittings

7. Visual Investigation Of Turbulent Pipe Flow

8. Experiments On Flow Rate And Pressure- controlled Systems

Services Required:

1. Water Supply.

2. Electrical Supply, 240/440V,3Ph, 50 Hz.

91-9829132777

91-9829132777