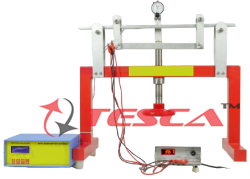

Deformation of Straight Beam

Order Code: 32134

Category: Strength of Materials Lab

Deformation of a beam on two or more supports under point loads (e.g. single-span beam) Deformation of a cantilever beam under point loads Statically determinate or indeterminate systems Beams are key structural elements i...

SPECIFICATION

- Deformation of a beam on two or more supports under point loads (e.g. single-span beam)

- Deformation of a cantilever beam under point loads

- Statically determinate or indeterminate systems

Beams are key structural elements in mechanical engineering and in construction. A beam is a bar-shaped component in which the dimensions of the cross-section are much smaller than the length and which is subjected to load along and perpendicular to its longitudinal axis. The load perpendicular to the longitudinal axis causes a deformation of the beam - that is, bending. Based on its size, the beam is viewed as a one dimensional model.

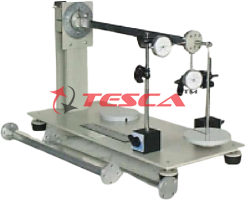

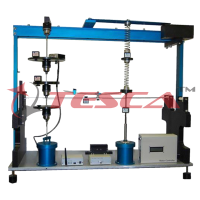

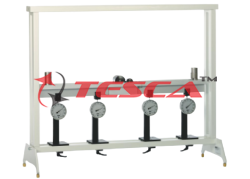

The science of the strength of materials deals with stress and strain resulting from the application of load to a component. Many fundamental principles of the strength of materials can be illustrated well by a straight beam. The beam under investigation in Tesca Deformation of Straight Beam Apparatus can be supported in different ways. This produces statically determinate and indeterminate systems which are placed under load by up to four sets of weights. The load application points are movable. Three dial gauges record the resulting deformation. Three articulated supports with integral force gauges indicate the support reactions directly. The articulated supports are height-adjustable, so as to compensate for the influence of the dead weight of the beam under investigation. A fourth bearing clamps the beam in place.

Five beams of different thicknesses and made of different materials demonstrate the influence of the geometry and of the modulus of elasticity on the deformation of the beam under load.

The various elements of the experiment are clearly laid-out and housed securely in a storage system. The complete experimental set-up is arranged in the frame.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications:

Elastic lines of statically determinate and indeterminate beams under various clamping conditions

3 steel beams with different cross-sections

1 brass and 1 aluminum beam

3 articulated, height-adjustable supports with a force gauge

1 support with a clamp fixing

Force gauges can be zeroed

3 dial gauges to record deformations

4 sets of weights with adjustable hooks

Anodized aluminum section frame housing the experiment

Storage system to house the components

Technical Specifications:

Beam

- Length: 1000mm

- Cross-sections

3x20mm (steel)

4x20mm (steel)

6x20mm (steel, brass, aluminum)

Frame opening: 1320x480mm

Measuring ranges

- Force: -50..+50N, graduations: 1N

- Travel: 0...20mm, graduations: 0,01mm

Weights

- 4x 2,5N (hanger)

- 4x 2,5N

- 16x 5N

Experiments:

Investigation of the deflection for statically determinate and statically indeterminate straight beams

- Cantilever beam

- Single-span beam, dual- or triple-span beam

- Formulation of the differential equation for the elastic line

Deflection on a cantilever beam

- Measurement of deflection at the force application point

Deflection of a dual-span beam on three supports

Measurement of the support reactions

Measurement of the deformations

Influence of the material (modulus of elasticity) and the beam cross-section (geometry) on the elastic line

Maxwell-Betti coefficients and law

Application of the principle of virtual work on statically determinate and indeterminate beams

Determination of lines of influence

- Arithmetically

- Qualitatively by way of force method (Müller-Breslau)

Scope of Delivery:

1 frame

5 beams

4 supports

4 sets of weights

3 dial gauges

1 storage system

1 set of instructional material

91-9829132777

91-9829132777