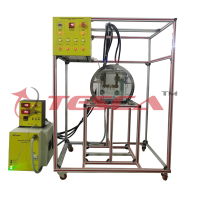

Condensation Process Apparatus

Order Code: 32322

Category: Thermodynamics Lab

Features Visualization of different condensation processes Software for data acquisition Condensation forms when steam meets a medium with a lower temperature than the saturation temperature for the existing partial pressure of the steam. Factor...

SPECIFICATION

Features

Visualization of different condensation processes

Software for data acquisition

Condensation forms when steam meets a medium with a lower temperature than the saturation temperature for the existing partial pressure of the steam. Factors such as the material and surface roughness of the medium influence the heat transfer and thus the type of condensation. In practice, it is usually film condensation. Drop wise condensation only forms when the cooling surface is very smooth and poorly wettable, e.g. Teflon. Knowledge of condensation processes is applied e.g. in steam power plants or at distillation processes.

Tesca Condensation Process Apparatus experimental unit can be used to demonstrate the different condensation processes using two tubular shaped water-cooled condensers made of different materials. Drop-wise condensation can be demonstrated by means of the condenser with a polished gold-plated surface. Film condensation forms on the matt copper surface of the second condenser, thus making it possible to examine film condensation. The tank can be evacuated via a water jet pump in order to vary the pressure in the tank together with the heating temperature and to set the boiling point. Sensors record the temperature, pressure and flow rate at all relevant points. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included. The heat transfer coefficient is calculated from the measured values. The influence of non-condensing gases, pressure and the temperature difference between the surface and steam can be examined in further experiments. The well structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments

Specifications:

Visualization of the condensation process of water in a transparent tank

Two water-cooled tubes as condensers with different surfaces to realize film condensation and dropwise condensation

Controlled heater to adjust the boiling temperature

Water jet pump to evacuate the tank

Pressure switch and safety valve for safe operation

Sensors for temperature, pressure and flow rate with digital display

Sci-Cal software for data acquisition via USB under Windows Vista or Windows 7

Technical Specifications

Heater

Output: 3kW, freely adjustable

Condenser

1x tube with matt copper surface

1x tube with a polished gold-plated surface

Water jet pump

Flow rate: 4...12L/min

Max. delivery pressure: 16mbar

Safety valve: 2200mbar absolute

Measuring ranges

Pressure: 0...4bar absolute

Flow rate: 0,2...6L/min

Temperature: 0...200°C

Optional ‘Sci-Cal’ software & hardware

‘Sci-Cal’ software & hardware has been designed for use with more than 200 ‘Tesca’ trainers. ‘Sci Cal’ comes in a module that can be fitted or mounted on the Tesca trainers very easily. ‘Sci-Cal’ box has 10 inches front HMI interactive panel, inside are i3 processor computer with it’s own hard drive & software processor with 16 to 32 analog and 16 to 32 digital signal data-loggers. The ‘Labview’ processes the input signal with in-built data and formulae to tabulate results for the Tesca trainers.

‘Sci-Cal’ box has HDMI output for connection to a projector or an electronic whiteboard or a monitor. ‘Sci-Cal’ box has input ports for inputs from the Tesca trainer sensors.

‘Sci-Cal’ eliminates requirement of external computer.

Specifications:

10” HMI panel front

HDMI output for connection to a projector or an electronic whiteboard or a monitor

In-built i3 computer processor & hard drive 16 to 32 analog and 16 to 32 digital input signal data-loggers

PID Computer Control + Data Acquisition + Data Management.

Compatible with actual Windows operating systems. Graphic and intuitive simulation of the process in screen.

Compatible with the industry standards.

Registration and visualization of all process variables in an automatic and simultaneous way.

Flexible, open and multi-control software, developed with actual windows graphic systems, acting simultaneously on all process parameters.

Analog and digital PID control.

Menu for PID and set point selection required in the whole work range.

Management, processing, comparison and storage of data.

Sampling velocity up to 250 KS/s (Kilo samples per second).

Calibration system for the sensors involved in the process.

It allows the registration of the alarms state and the graphic representation in real time.

91-9829132777

91-9829132777