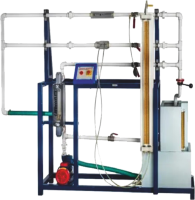

Compressible Flow of Fluids Apparatus

Order Code: 32076

Category: Fluid Mechanics Lab

Features: Investigation of flow in compressible fluids1 Varied range of experiments for studying subsonic and transonic flow1 de Laval nozzle generates velocities up to Ma 1 Compressible fluids change their density due to pressure change in the f...

SPECIFICATION

Features:

Investigation of flow in compressible fluids1

Varied range of experiments for studying subsonic and transonic flow1

de Laval nozzle generates velocities up to Ma 1

Compressible fluids change their density due to pressure change in the flow. Flows with velocities less than Ma 0,3 are regarded as incompressible and the change in density is negligible. At higher velocities, the density has to be included in calculations. These conditions must be taken into consideration when designing e.g. turbo compressors, jets, and fast planes.

Tesca Compressible Flow of Fluids Apparatus is used to investigate airflow in various ranges of velocity.

A radial fan with infinitely variable speed control draws in air from the environment. At the intake, the airflow is accelerated in a measuring nozzle. Further down the measuring section, the air flows through interchangeable measuring objects. Drawing in the air and the arrangement of the measuring objects on the intake side of the fan minimize turbulence when flowing into the measuring objects. All measuring objects are made of transparent material and provide excellent insight into the inner structure.

Pressure losses are studied in a pipe elbow, various pipe sections, and a nozzle with sudden enlargement. The nozzle with a gradual enlargement (de Laval nozzle) provides an introduction to the topic of transonic flow. The volumetric flow rate is measured in an orifice using a differential pressure manometer. The orifice is fitted with four interchangeable orifice disks for different measurement ranges. The fan's characteristic curve can also be recorded by using a throttle valve.

The measured values for volumetric flow rate, pressure, and speed are displayed digitally. The well- structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications:

Investigate the flow of compressible fluids

Subsonic and transonic airflow

Variable speed on the radial fan for adjusting the mass flow

Minimized turbulence by drawing in air and optimum arrangement of the measuring objects

Transparent measuring objects with connectors for pressure measurement provide insight into the internal structure

Measuring nozzle for determining the mass flow

Pressure losses in subsonic flow in pipe elbows and various pipe sections

Pressure curve at subsonic and transonic nozzle flow

Orifice for determining volumetric flow rate by differential pressure measurement

Record fan characteristic curve using a throttle valve

Digital displays for pressures, velocity, and speed

Data Logging with educational software and electronic temperature sensors

Technical Specifications:

Radial fan

Max. speed: 34000min-1

Max. volumetric flow rate: 206m³/h

Max. head: 271bar

Max. power consumption: 1,6kW Measuring objects

Pipe section: 1m, diameter: 16, 24, 34mm

90° pipe elbow

2 nozzles, inner diameter: 12...34mm with sudden enlargement

With a gradual enlargement (de Laval nozzle)

Orifice with orifice disks, diameter: 12, 19, 25, 32mm

Throttle valve, diameter: 34mm Measuring ranges

- Speed: 0...99999min-1

Pressure: 1x 0...25mbar, 1x 0...200mbar, 1x 0...1000mbar

velocity: 0...65m/s

Experiment Capabilities:

Pressure losses in pipes and pipe elbows

Flow in convergent/divergent nozzles

Supersonic flow in the de Laval nozzle

Determine the speed of sound in the air

Compare calculation methods for incompressible and compressible flow

Use complete continuity equation

Determine mass flow using nozzle and volumetric flow rate using orifice

Record calibration curve for orifice

Record fan characteristic curve at different mass flows and speeds

Required Services:

Electric Supply 230V AC, Single Phase, Earthed.

91-9829132777

91-9829132777