Chemical Reactors – Teaching Equipment

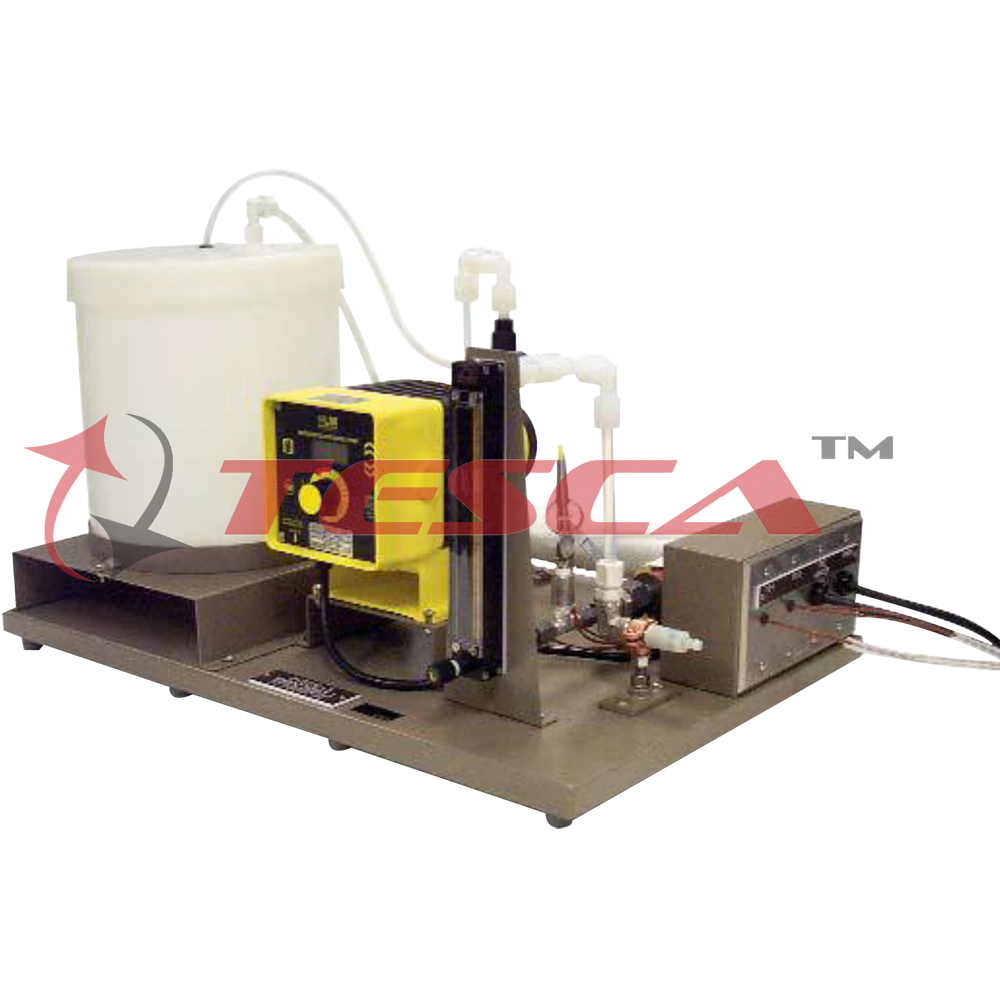

Order Code: 32262

Category: Thermodynamics Lab

Features Compact, mobile unit, designed to provide required services for testing various Reactors using single source. Provides PID temperature controlled hot water in order to maintain reactor temperature Comprehensive Instrumentation Pane...

SPECIFICATION

Features

- Compact, mobile unit, designed to provide required services for testing various Reactors using single source.

- Provides PID temperature controlled hot water in order to maintain reactor temperature

- Comprehensive Instrumentation Panel with all necessary safety instruments.

Tesca Chemical Reactors Teaching Equipment Model TH 010 is a self-contained bench top service unit designed to provide services for different chemical reactors. The reactors can be easily mounted on to the service equipment & all the Reactor modules can be studied on same service unit.

It includes a hot water re-circulator used to control the temperature of the reactions, glass feed vessels for the reactants, two peristaltic pumps to pump the reagents to the reactors.

The service module also includes required measuring instruments & Data Acquisition Device which can interface with computer through USB Port. Sensors are provided for measuring temperature, conductivity at & flow rate for analysis.

The entire setup is mounted on sturdy steel frame made of Steel Tubes & Sheets. The entire frame & panel are powder painted for durability.

Data Acquisition Software provides real time data on computer screen along with graphs & tabular results.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Technical Specifications

Hot Water Tank with Heater Controller.

Two peristaltic feed pumps with individually variable flow rates, 0-140 ml/min.

Complete with two thermocouples, an input for a third (user) thermocouple and a dual range conductivity sensor.

Fully computer controlled and supplied with educational software (32/64 bit) specific to each reactor type. Simple interfacing to the (user supplied) computer by a USB interface.

Provides PID temperature controlled hot water in order to maintain reactor temperature.

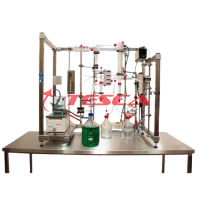

TUBULAR REACTOR; Order code - 32263

Tubular Reactor is in the form of a tube wrapped in a spiral around an acrylic former which is enclosed in a transparent tank. Water at a controlled temperature service module is circulated within the tank, this maintains the reactants at constant temperatures. The reagents are separately piped to the reactor through quick release fittings mounted on the lid and are pre-heated in stainless steel coils in the water tank, before being mixed and fed into the reactor coil.

Experiment Capabilities

Determination of reaction rate constant

Investigation of the effect of throughput on conversion

Demonstration of the temperature dependence of the reaction and the rate constant

Determination of the residence time distribution

Study of the effect of flow rate on conversion

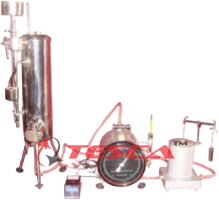

Continuous Stirred Tank Reactor; Order Code - 32264

Tubular Reactor is in the form of a tube wrapped in a spiral around an acrylic former which is enclosed in a transparent tank. Continuous stirred tank is a small scale demonstration version for educational use. It is extremely flexible in use and can be used for both continuous and batch reactions.

The temperature sensor & conductivity probe can be positioned in the reactor vessel. A stainless steel coil is used for temperature control of the reactor from the hot water supply on the service module. A variable speed mixer/agitator is included together with baffles to improve the mixing.

Experiment Capabilities

Effect of residence time on conversion

Determination of reaction rate constant Residence time distribution

Evaluation of empirical rate expressions from experimental data

Effect of temperature on reaction rate

Effect of mixing on reaction rate

Effect of flow rate on conversion

Services Required

Electric Supply 230 V AC, 16 A, Single Phase, Earthed.

Cold Water Supply & Drainage.

Personal Computer with USB port, Windows operating system & all peripherals.

91-9829132777

91-9829132777