Buckling Behaviour of Bars

Order Code: 32146

Category: Strength of Materials Lab

Features Investigation of all relevant buckling problems Verification of the Euler Theory of buckling Methods of force and deflection measurement Supplementary set for experiments with eccentric application of force and transv...

SPECIFICATION

Features

- Investigation of all relevant buckling problems

- Verification of the Euler Theory of buckling

- Methods of force and deflection measurement

- Supplementary set for experiments with eccentric application of force and transverse loading

- Comprehensive instructional material

In technical mechanics, loss of stability is known as buckling. Under the effects of compressive forces, and under increasing load, the axis of the bar deflects laterally until it suddenly and violently fails (collapses), even before the fracture point is reached. The stresses in the bar often remain within the elastic range during this process.

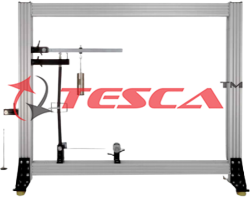

Tesca Buckling Behavior of Bars investigates the buckling behavior of bars under various influences. All relevant buckling problems are demonstrated by way of experimentation.

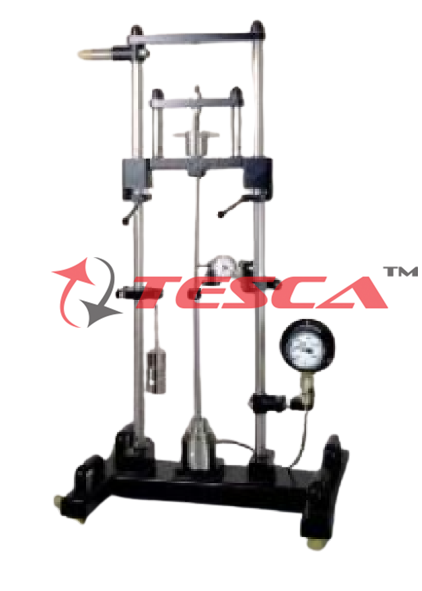

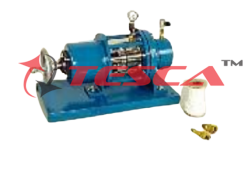

For this purpose, one end of a bar is fixed or pinned, depending on the buckling case. A height-adjustable load-carrying cross-arm and a hand-operated spindle are used to apply a compressive force to the bar. An axial bearing between the spindle and the bar support prevents torsional loading of the test bar. A hydraulic load cell measures the applied force and indicates it on a pressure gauge. The lateral deflection of the bar is indicated on a dial gauge.

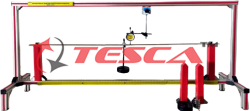

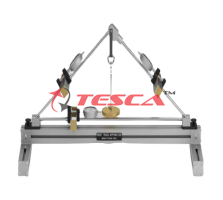

Experiments demonstrate various influences, such as bar lengths, materials, and methods of support. A transverse load application device can be used to generate additional shear forces on the test bar. The experimental unit can be operated vertically or horizontally. The load gauge can be rotated 90° to adjust to the chosen option. A supplementary set extends the scope of experimentation offered by Tesca Buckling Behavior of Bars. The various elements of the experiment are clearly laid-out and housed securely in a storage system.

Specifications

Investigation and testing of all relevant buckling cases

Verification of the Euler Theory of buckling

Experiments in horizontal or vertical orientation

Test bars in various lengths and materials

Test bar ends pinned or fixed

Spindle to apply forces

Transverse load application device generates shear forces

Force measurement using a hydraulic load cell

Measurement of lateral deflection by dial gauge

Additional experiments with supplementary set

Storage system to house the components

Technical Specifications

Test bars

- Quantity: 11

- Bar length: 350...700mm (max.)

- Material: aluminum, copper, brass, steel, GRP

- Cross-sections: 10x4mm, 25x6mm, 25x10mm

Load application spindle

- Force: max. 2000N

- Stroke: max. 10mm

Lateral deflection: max. 20mm

Specimen holder bore: d=20mm

Measuring ranges

- Force: 0...2500N, graduations: 50N

- Deflection: 0...20mm, graduations: 0,01mm

Set of weights for transverse load: max. 20N

- 3x 5N, 1x 5N (hanger)

Experiments

Investigation of buckling behavior under the influence of

- Various methods of support

- Various bar lengths, cross-sections

- Various materials

Verification of the Euler Theory: buckling on elastic bars

Determination of the modulus of elasticity for an unknown material (GRP)

Measurement of force and deflection

Calculation of the expected buckling force by the Euler formula

Graphical evaluation of deflection and force With supplementary set

Investigation of buckling behavior under the influence of

- Various cross-sectional shapes

- Eccentric application of force

- Additional transverse loading

Scope of Delivery

- 1 experimental unit

- 11 test bars

- 1 dial gauge with bracket

- 1 storage system

- 1 set of instructional material

91-9829132777

91-9829132777