Bending Of Beam - Uniaxial

Order Code: 32164

Category: Strength of Materials Lab

Features Symmetrical and unsymmetrical bending on a beam Symmetrical and unsymmetrical cross-sectional profiles: I, L and U Combined bending and torsion loading by way of eccentric force application Bending of a beam symmetrically - also known as...

SPECIFICATION

Features

Symmetrical and unsymmetrical bending on a beam

Symmetrical and unsymmetrical cross-sectional profiles: I, L and U

Combined bending and torsion loading by way of eccentric force application

Bending of a beam symmetrically - also known as uniaxial bending - occurs when the load plane coincides with one of the main axes of the beam cross-section. The beam then deflects in the direction of the load and can be described by elastic lines.

In unsymmetrical bending of a beam - also known as complex or biaxial bending - the main axes of the cross-section do not coincide with the direction of loading. To prevent torsion, the line of application of the load must pass through the shear centre. If it does not, the beam undergoes combined bending and torsion loading.

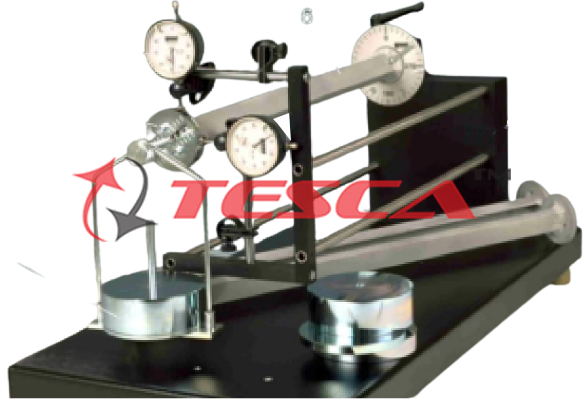

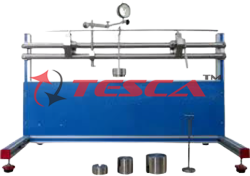

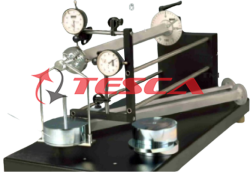

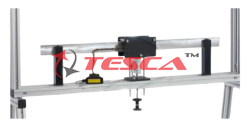

Tesca Bending of Beams: Uniaxial or Unsymmetrical is used to perform experiments relating to symmetrical and unsymmetrical bending and to combined bending and torsion loading. The beam under investigation is clamped into place on one end and loaded down by a set of weights at the free end. Two dial gauges record the horizontal and vertical deformation of the beam. The unit includes three beams with different cross-sectional profiles: I, L and U. The beam can be clamped with freedom to rotate in any direction. This enables investigation of loading along the main axis or of the general load case. An angle scale at the clamping point indicates the angular position of the beam. It is possible to adjust the load application point eccentrically, so that purely unsymmetrical bending or combined bending and torsion loading is investigated.

The various elements of the experiment are clearly laid-out and housed securely in a storage system. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications

Experimental unit for general and unsymmetrical bending of straight beams

3 beams: I, L and U profiles

Clamping flange of beam can be clamped in the pillar free to rotate in any direction

Clamping flange with angle scale to indicate the angular position of the beam

Eccentricity of load application point adjustable

2 dial gauges with bracket to record the horizontal and vertical deformation of the beam under load

Storage system to house the components

Technical Specifications

Aluminum beam

Deformed length: 500mm

The eccentricity of load application point: 0...25mm

Dial gauges

0...10mm, graduations: 0,01mm

Angle scale

- 0...360°, graduations: 1°

Weights set

1x 2,5N (hanger)

- 1x 2,5N

3x 5N

Experiment Possibilities

Product moment of inertia (Iyz) and 2nd moment of inertia (Iy, Iz)

Euler/Bernoulli equation

Symmetrical bending on a beam (uniaxial)

With I-profile

With L-profile

With U-profile

Unsymmetrical bending (complex) on a beam with an L-profile

Calculation of the neutral fibres

Combined bending and torsion loading by way of eccentric force application

Determination of the shear centre on a beam with a U-profile

Familiarization with shear flow (shear forces in a cross-section)

Comparison of calculated and measured values

Scope of Delivery

1 experimental unit

3 beams

2 dial gauges with bracket

1 set of weights

1 spirit level

1 hexagon socket wrench

1 storage system with foam inlay

1 set of instructional material

91-9829132777

91-9829132777