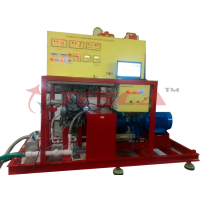

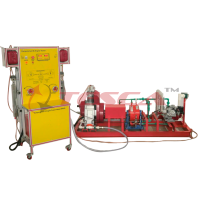

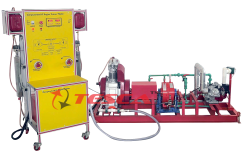

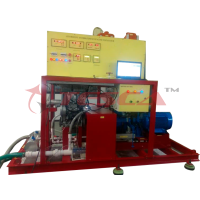

4 Stroke 1 Cylinder Diesel Engine Test Bed With QAD

Order Code: 32745

Category: Technology Trainers

Tesca AutoSci-Cal Engine Cycle Analyzer Module AMECA is a versatile module consisting of both hardware and software specially designed for educational use. It enables students to investigate the relationship between crank angle or volume and the cyli

SPECIFICATION

Features

- Designed for comprehensive analysis of performance of different automobile engines.

- Digital Instruments for measurement of parameters like fuel consumption, air flow, temperature and RPM etc.

- Demonstration of performance of Diesel Engines at different throttle settings & Loads.

- Optional High Speed Data Acquisition system for performance monitoring.

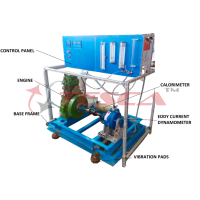

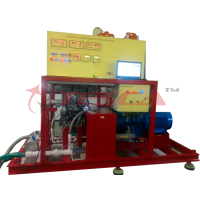

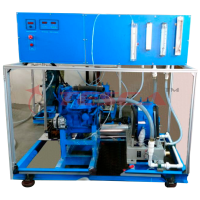

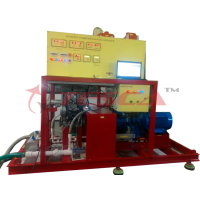

- Tesca Automotive 4 Stroke 1 Cylinder Diesel Engine Test Bed 32745-32746 are designed to felicitate testing of different automobile diesel engines. The test bed is complete with eddy current dynamometer and measuring instruments for measuring key engine parameters required for performance analysis of an engine. The test bed can be used for testing of diesel engines rated up to 3 kW.

- The test bed consists of a water cooled eddy current dynamometer or Rope-Brake dynamometer, fixed on a heavy-duty steel frame. The test bed is designed in such a way that the engine to be tested can be quickly coupled to the dynamometer with minimum effort. The test bed is equipped with dynamometer control panel with necessary safety instruments. The Engines can be used for performance tests for different loads and speeds under various throttle opening conditions. The eddy current dynamometer provides a variable load on the engine, allowing the characteristic power and torque curves to be reproduced in the laboratory. The system comes complete with extensive instrumentation, including rpm measurement, torque (from which power can be calculated), plus various temperatures, Fuel Consumption, Air Consumption.

- Different optional accessories are available to integrate with the Engine Test Bed for comprehensive engine performance analysis. These include the exhaust gas calorimeter (For Heat Balance Sheet), advance Data Acquisition System & P-V Diagram module for computerized testing.

Specifications

Eddy current or Rope-Brake Dynamometer: Capacity: 2 - 3kW, Water Cooled

Optional:

Rope brake dynamometer with loading unit

Electrically Dynamometer with loading unit

Hydraulic Dynamometer with Pump & Sump tank and loading unit

Dynamometer Controller

Engine: Air cooled; 318cc; 1800 RPM; 2.94KW Diesel Engine mounted on mobile frame

(Note: Additional Engines can be supplied on request.)

Air Box with Orifice plate for Air flow measurement.

Fuel Tank: for Diesel.

Propeller shaft with protective covering.

Measuring Instruments –

Engine RPM Sensor

Differential Pressure Transmitter for Air

Fuel Level Sensor

Thermocouples

Torque Sensor

Accessories:

Battery for starting the engines

Set of Anti Vibration Pads

Auxiliary cooling unit for engine

Exhaust Gas Calorimeter (Optional)

Cooling Water Flow Transmitter

Pipe In pipe type heat exchanger

Thermocouples for water & gas temperature.

Data Acquisition System & Software (Optional)

Signal Converter

Data Acquisition Card, 16 Channel High speed DAQ Card with USB Port

Software: Labview based software for data acquisition, real time display, graphical representation, calculation & tabular results.

P-V Diagram Module (Optional)

Engine cylinder pressure

Crank angle Encoder

AutoSci-Cal® Engine Cycle Analyzer Module AMECA (Optional)

Features

- Significantly enhances practical investigations, demonstrations and studies of internal combustion engines

- For use with Smaller capacity Engine Test Sets and Regenerative Engine Test Set and engines

- Factory fitted with suitable cylinder head transducers and crank angle encoders

- Includes powerful Windows based software specially designed for educational use

- Automatic calculation and real-time display of p-q plots and p-V plots and other important parameters

- Useful snap-shot, replay and animation functions

- Accurate, clear animations of crank, piston, inlet and exhaust valve positions help students visualise the engine cycle

- Ideal for student experiments, laboratory demonstrations or project work, Engine Cycle Analyzer enables students to investigate a variety of engine performance characteristics.

- Students can export data for further analysis

Tesca AutoSci-Cal Engine Cycle Analyzer Module AMECA is a module with hardware and software to measure internal combustion engine cylinder pressure and crank angle.

Tesca AutoSci-Cal Engine Cycle Analyzer Module AMECA is a versatile module consisting of both hardware and software specially designed for educational use. It enables students to investigate the relationship between crank angle or volume and the cylinder pressure in an internal combustion engine. The equipment is primarily for use with engine test sets and engines but it can also be used with other engines fitted with compatible cylinder head transducers and crank angle encoders.

The equipment consists of a hardware unit with connectors and leads, plus Windows based data acquisition and analysis software. The hardware consists of a microprocessor-based signal conditioning unit with high-speed PC interface, housed in a rugged, protective enclosure. It accepts and conditions signals from the Cylinder Head Pressure Transducer and Crank Angle Encoder, pre-mounted on the engines. The cylinder pressure input includes a precision charge amplifier with a digital calibration. Crank angle position, the signal from the Crank Angle Encoder is also used to determine engine speed.

The output from the hardware unit connects to a computer (computer not included) running the Engine Cycle Analyser software. The hardware unit includes LED indicators to show the processor readiness, encoder top deadcentre position and PC communication status.

The software provides real-time display of pressure versus crank angle (p-q) and pressure versus volume (p-V) plots.

It performs calculations on the data to accurately display indicated mean effective pressure (IMEP) and indicated power for comparison with brake mean effective pressure (BMEP), and brake power to determine the mechanical efficiency of the test engine.

The software has useful snap-shot, replay and animation functions to help students visualise and better understand the engine cycle. The snap-shot and replay allow students to capture several engine cycles and study them using an animation showing the relative position of the crank, piston, inlet and exhaust valves. The software also allows students to create and recall engine configuration files for convenient entry of test engine data needed for calculations such as crank radius and engine swept volume. Data can also be exported to other software for further analysis.

Experiment Possibilities

- Module AMESA allows investigations into a variety of internal combustion engine characteristics, including:

- The thermodynamic cycle of an internal combustion engine

- Calculation of indicated mean effective pressure and indicated power

- Comparison of indicated mean effective pressure and brake mean effective pressure

- Mechanical efficiency of the test engine

- Further work using exported data such as combustion analysis

- Extra Ancillaries (fitted on engines)

- Cylinder Head Pressure Transducer

- Crank Angle Encoder

- Recommended computer hardware:

- Intel® Pentium® 4 or equivalent processor operating at 2 GHz

- 512 MB of RAM

- SVGA monitor with 16-bit colour, 1024 x 768 resolution

- CD-Rom drive

- USB 1.1 or 2 port

- 500 MB of hard disc space

- Two-button mouse

Operating system:

Microsoft® Windows XP, Vista, Windows 7 and 8

Standard Features

Supplied with comprehensive user guide

Made in accordance with the latest European Union Directives

Requirements:

Electrical supply:

Single-phase a.c. 90 to 240 V, 50/60 Hz

Operating Conditions

Operating environment: Well ventilated laboratory

Storage temperature range: –25°C to +55°C (when packed for transport)

Operating temperature range: +5°C to +40°C

Operating relative humidity range: 80% at temperatures < 31°C decreasing linearly to 50% at 40°C

Experiments

- Investigate Engine Performance at different Throttle Settings & Load conditions.

- Calculation of Mechanical Efficiency & Plot brake power versus mechanical efficiency.

- Measurement & Calculation of Volumetric efficiency.

- Measurement & Calculation of specific fuel consumption

- Measurement & Calculation of brake thermal efficiency

- Determining air / fuel ratios

- Heat Balance Test (With Optional Exhaust Gas Calorimeter)

- Study of P-q & P – V Diagram for Engine (With optional P-V Module & Data Acquisition System).

Scope of Delivery

1 engine, complete with all connections and supply lines

One set of tools

1 manual

91-9829132777

91-9829132777