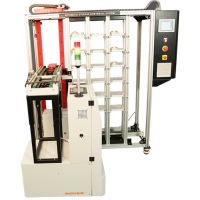

4 Axis CNC Milling Machine for High Precision Desktop Milling

Order Code: 54005

Category: Mechatronics/ Robotics/ CNC Lab

Compressed Air Supply minimum 6 bar pressure 5KVA Servo Stabilizer , Single phase (if fluctuation is high) PC With latest configuration of at least 8GB RAM, 520GB Hard disk, Minimum Windows 7 Operating system, built-in graphics displays and NVIDIA

SPECIFICATION

|

|

|||

|

|

SPECIFICATIONS |

||

|

|

Travel |

||

|

|

Travel in X |

mm |

100 |

|

|

Travel in Y |

mm |

190 |

|

|

Travel in Z |

mm |

100 |

|

|

Rotation axis |

Deg |

± 360 |

|

|

Capacity |

|

|

|

|

Tool Collet Size |

mm |

Dia 3 |

|

|

Disk Size |

mm |

Dia 100 x 10-30 mm |

|

|

Machiniable Materials |

|

Wax, Zircon and CoCr (Pre-sintered) |

|

|

Spindle |

||

|

|

Spindle |

Size |

High frequency Motorised Spindle |

|

|

Spindle Speed range |

RPM |

5000-60,000 |

|

|

Spindle Power |

Kw |

240W |

|

|

Axes |

||

|

|

Axis Resolution |

mm |

0.001 |

|

|

Axis Accuracy |

mm |

0.01 |

|

|

Axis Repeatability |

mm |

±0.005 |

|

|

Guide Ways |

Z-Axis |

15 CA / H Grade / Ball Type |

|

|

Ball Screw X,Y&Z |

mm |

Dia 16 x 5 / C3 Class |

|

|

Rapid Motion Speed and Feed Rate X ,Y& Z |

m/min |

1.5 |

|

|

Programmable Feed Rate |

m/min |

1.5 |

|

|

Axes Motor Torque X ,Y& Z |

Nm |

2 |

|

|

Axis motor |

|

Stepper type |

|

|

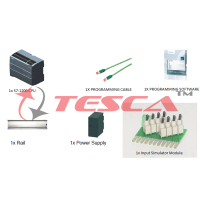

Controller |

||

|

|

Controller Type |

|

Dedicated CNC Control |

|

|

No of Simultaneous Axis |

|

4 |

|

ATC |

|

|

|

|

No. of Tool Stations |

Nos. |

6 |

|

|

Shank Diameter for Tool |

mm |

Dia 3 mm |

|

|

Automatic Tool Offset Sensor |

|

Yes |

|

|

Tool Breakage Sensor |

|

Yes |

|

|

Power Source |

|||

|

Voltage Supply Std (Other options avl on request) |

V |

110V or 230V±2%, Single Phase, 50/60 Hz |

|

|

Power Requirement |

KVA |

2 |

|

|

Dimensions |

|||

|

Dimensions L x W x H |

mm |

605X900X770 |

|

|

Total Weight |

kg |

130 |

|

|

Mist Coolant |

|

Optional |

|

|

Vacuum Outlet |

|

Yes |

|

|

CAM Software |

|

Maykadent |

|

|

Tools: 1 set of roughing and finishing tool for Zircone, 1 set of roughing and finishing tool for Wax, PMMA |

|||

|

|

|||

TILITIES TO BE ARRANGED BY THE BUYER AT SITE

- Compressed Air Supply minimum 6 bar pressure

- 5KVA Servo Stabilizer , Single phase (if fluctuation is high)

- PC With latest configuration of at least 8GB RAM, 520GB Hard disk, Minimum Windows 7 Operating system, built-in graphics displays and NVIDIA GEForce GTX 745 or better, Display unit, Mouse, Keyboard and with UPS. Full computer configuration will be provided along with proforma invoice

91-9829132777

91-9829132777