Table of Contents

As soon as you hear Cochran Boiler, you may think in your mind that what kind of boiler is it?

Today, we are here to let you know all about the Cochran boiler’s functions, characteristics, and application here. So let’s get started then:

What is a Cochran or Vertical Water Tube Boiler?

This device has multiple horizontal fire tubes attached to it. A Cochran Boiler is generally a type of boiler with a vertical fire tube, and these fire tubes are multi tubular. Compared to a normal boiler or an ordinary vertical boiler, the boiler is way more efficient.

In short, a Cochran boiler is a modified version of a vertical boiler wherein the fitting surface is extended with the help of several fire fats.

Image Credit:Learnmech.com

Cochran Boiler is a revolutionary new way to boil water. It can do so without any fossil fuels or electricity. It uses patented technology that makes the water inside the boiler produce its own steam through condensation, thereby boiling itself.

What are the different uses of Cochran Boiler?

There are quite a lot of uses of a Cochran boiler. The main purpose of the Cochran Boiler is to heat the water to produce steam.

A Cochran boiler is a device that works to convert heat energy into steam energy. It is used in large-scale heating systems where steam is used.

Cochran boilers can be used in the small steam requirements that are one of the basic needs in industries. The main use of a Cochran boiler is to produce steam from water by heating it.

Compared to most boilers, this one is a bit easy to operate and can be installed quite conveniently. Moreover, the Cochran boiler takes less manpower and provides a higher volume to area ratio, giving enough room to produce more steam.

Also, Read Soldering & Desoldering Rework Station.

Working of the Cochran Boiler:

The Cochran Boiler doesn’t have a complex work process.

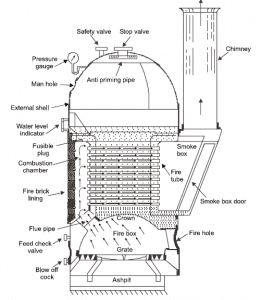

Step 1: Loading and Igniting the Fuel Item:

First of all, the fuel is inserted into the firework that is placed on the Grate of the boiler. After igniting the fuel from the fire hole, the fuel is burnt from where the hot flue gases and smoke come out.

These gases are directed to the combustion chamber from where it enters the Fire tubes surrounded by water.

Step 2: Storing the Steam:

The hemispherical shell on the top of the boiler makes it spacious for the steam, which gives it enough room to increase the capacity of the steam on the hemispherical peak area of the boiler.

As the temperature rises in the boiler, the water starts boiling, and then it is converted into steam. This steam moves upward and then is collected at the top of the boiler. the boiler is shaped as a hemispherical dome.

Step 3: Converting into Dry Steam:

After his, the process anti plumbing pipe is installed from where the water is separated from the steam, which converts into dry steam. This is further transferred into the turbines with the help of the steam stop valve at the top of the boiler.

From here, the burnt gases and smoke are discharged. These are discharged through the chimney into the atmosphere.

Next, at the top of the combustion chamber, there is a fusible plug that melts after the combination chamber crosses the temperature, and this is when the water enters into the Furnace and stops the fire.

By doing so, any kind of fire accident can be prevented so that it won’t damage the boiler with rising temperature.

What is the main application of the Cochran Boiler?

The Cochran Boiler is a steam boiler that makes use of liquid fuel, usually oil or liquid petroleum gas.

It was first developed by the Scottish engineer Thomas Russell Cochran in 1887. Cochran boilers are used for industrial heating and refrigeration applications.

Applications include steam power, pulp, and paper, oil refining, petrochemical, chemical processing, pharmaceutical, cryogenic research, food processing, marine cargo transport refrigerated shipping containers.

These boilers are used in power generation plants. These plants have large quantities of steam with approximate high pressure ranging up to 500 kg/s, and temperature may reach a level of 550°C.

The application of these boilers can be made in the refining units. It is also used in paper manufacturing plants for chemical processing divisions.

Cochran Boiler Construction: Components and Parts

A Cochran boiler is constructed with different kinds of parts and components. Let us know about these parts and also discuss them briefly:

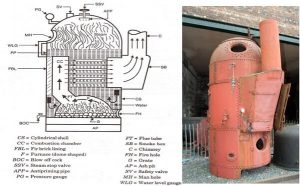

1. The Boiler Shell:

The boiler shell of a Cochran boiler is made up of a cylindrical form. It is welded together with the steel plate. The shell is close by endplates at the end, and it has enough capacity to store an amount of water and steam.

2. Grate:

The Grate is a part of a Cochran boiler where the fuel is burnt in the boiler’s combustion chamber. It is made up of a cast iron bath and also has space in between so that the air present in the boiler can pass through it.

3. Combustion Chamber:

The combustion chamber in the Cochran boiler is the area that is just below the boiler shell, and this chamber is used to generate steam from the water by burning the fuel.

4. Furnace:

The Furnace in a Cochran boiler is used for burning the fuel. It is just below the boiler shell and the part that is above the Grate.

5. Fire Tubes:

The horizontal tube that is between the combustion chamber is known as the fire tube. The fuel gases are formed from the combustion chamber, and from here, it goes through the fire tube. Then it exchanges the heat from hot fuel gases and changes it to water.

6. Chimney:

The chimney is a part of the Cochran boiler that is at the top of the boiler. It is connected to a smokebox wherein the gases come out from the fire tube and exhaust through the chimney.

7. Fire Hole:

A fire hole is a part that is just below the combustion chamber, and it is used for wiring the fuel inside the Furnace.

Add comment