Table of Contents

In product manufacturing industries, it is essential to check the overall strength or durability of the material to manufacture a robust product.

Some tools help find out about the durability of the material. One such helpful device or instrument is a Torsion Testing Machine.

Let us know in detail about this device here:

What is a Torsion Testing Machine?

‘A torsion testing machine is a device that uses a torsion beam to apply a twist to a specimen and measure the torque necessary to induce failure.’

Torsion testing machines are helpful in research, development, and production engineering to determine the ultimate tensile strength (UTS) or elastic modulus of materials.

In other words, it measures the amount of force required to deform an object. It applies tension and then subsequently measures the resulting torque.

The exact model of a torsion testing machine depends on its purpose – for example, a typical industrial test machine typically helps to hold heavier loads than a laboratory model.

These are essential in testing material quality and are widely helpful by industries.

Torsion Testing Machine Images:

These are some images of Torsion Testing Machines:

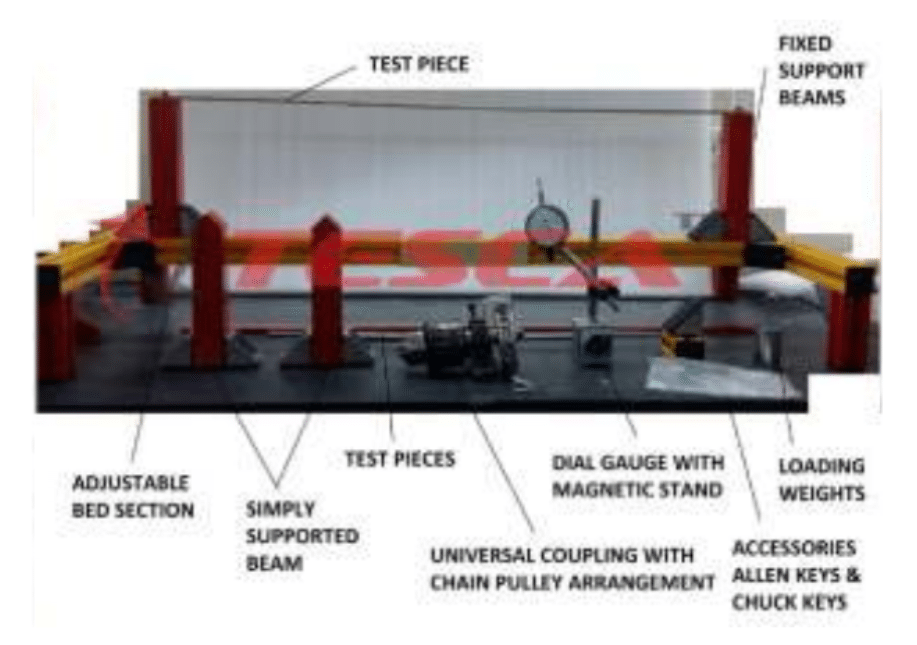

Various Parts of a Torsion Testing Machine Parts Name:

Now let us know more about torsion testing machines here:

It consists of several torsion testing machine parts:

- Strain head

- Torque reaction and measurement system

- Drive reduction gearbox

- Frame

- Keyway

- Accurate encoder

- Torsion shaft

- Lever arm

- Torque cell

- Drive sockets.

Let us know in detail about torsion testing machine components:

Most torsion testing machines have a strain head at one end and a torque reaction system.

A torsion testing machine consists of a lever arm, a torque cell for holding the sample, and a load cell for measuring the torque.

Usually, students turn a twist handle to apply force to drive the gears within the machine.

It guides a shaft lengthwise from input to output, which allows for any change in length of the specimen during the tests and easy insertion of samples.

An encoder measures any tilt or movement relative to continuous rotation. While this does not calculate the rotation angle directly, it displays the angular displacement on an analog display.

In addition, another gauge – measuring torsion forces – is built into one or both sides of the drivetrain.

For example, one meter may monitor rotation and the twist (torsion) while another side-to-side measure twisting but not forward-and-backwards bending (torque).

Uses of a Torsion Testing Machine:

Let’s know about some of the uses of a Torsion Testing Machine here:

- A torsion testing machine is an essential quality assurance instrument in the industrial sector, and it is helpful to ensure that the manufactured products can withstand applied stress and pressure.

- A torsion testing machine helps to entail a physical experiment used in labs to determine how things constructed out of various materials respond to torsional stress (e.g., twisting) when put under load due to opposing forces and moments.

- There are multiple values and units commonly associated with torsion testing, including Young’s Modulus, Shear Modulus, Shear Strength, Fatigue Life, Torsional Ductility, Ultimate Tensile Strength & Ductility, and Coefficient of Rupture in Tension / Compression tests respectively. They’re all significant in the labs because they regulate mechanical engineering practices via ensuring quality control (QC) before mass production runs to merely minimize defects or other issues while eliminating wasted production costs or wasted material/components (waste reduction).

Working Principle of a Torsion Testing Machine:

Have you ever wondered how a torsion testing machine works?

A torsion test is a non-destructive practical examination in materials engineering and mechanical engineering to determine the stiffness of an object.

Let us know about the principle of the testing machine here:

- A typical test involves using an instrument called a torsion machine to twist one end of the material that is subject to being turned to put stress on it. With this, the device reveals the internal deformation after being twisted for a specific time, indicating the elasticity and reduction in force needed to continue rotating the material.

- A torsion testing machine uses a rotating ball twist to drive a load-bearing crosshead up and down. An electrical motor controls a sequence of pulleys and gears that turn the screw, making the crosshead motion.

- The twisting force of a torsion test applies to the test sample by anchoring one end so that it cannot move or rotate and using a moment to the other end so that the model rotates about its axis.

Read also: What Is Hydraulic System and How Does it Work?

11 Various Types of Torsion Testing Machine:

If a material fails, it is subjected to the ultimate failure mode, usually plastic flow or fracture.

Torsion test machines help evaluate this type of mechanical behavior. As per the industry’s requirements, there are different Torsion testing machines.

Let’s know about some of the torsion testing machines:

1. Digital Torsion Testing Machines:

A Digital Torsion Testing Machine tests tensile strength or elasticity. It is a type of torsion testing machine that helps evaluate the tensile strength of materials.

The device will determine how many kilograms it takes to break a sample of the material after being put under stress and stretched, giving you an idea of its elasticity.

It measures the resistance to twisting materials by measuring their torque-twist characteristics.

It helps to test construction materials, paperboard, rubber, textiles, and other materials that are subject to stress while being twisted.

The results provide information about a material’s stiffness and ability to resist cracking or breaking.

In the digital torsion testing machine, the output of the test is shown on a digital display, which gives us a direct reading.

2. Torsion Spring Testing Machine:

The Torsion Spring Testing Machine is useful to test the strength of torsion springs which stores mechanical energy in twisting stress instead of compressive stress or tensile stress.

The machine can measure the maximum load capacity and the rate of elongation or contraction for spring by using different types of test samples.

Torsion Spring Testing Machine is a practical device to test the strength of the spring and ensure that it can withstand the given load.

A platen and upper head are gathered together with a base and lower head to form a complete model.

Torsion testing machines are mainly applied in mechanical industries like the automobile industry, aerospace industry, mining machinery industry, and other industries with significant demand for torsion springs.

3. Horizontal Torsion Testing Machine:

A horizontal torsion testing machine uses a special spring to exert force and then measure the necessary torque to twist an object by a given angle.

In addition to providing a regular pulling or pushing power, it gives a twisting moment.

This additional capability helps the operator to determine both the shear and tensile strength of materials.

It conducts the test on the tensile and flexural strength of tools and materials for the automobile industry.

4. Vertical Torsion Testing Machine:

The vertical testing machine is widely helpful in single column tests and two-column tests for engineering structures, such as nuclear power plant equipment, boilers, pressure vessels, bridges, large crane chassis, high-rise buildings, etc.

A vertical torsion testing machine helps determine the elastic properties, such as stiffness, toughness, and Young’s modulus.

The device employs a linear slide design for maximum torsional stiffness and minimal axial friction. It comes with a reaction torque transducer present to a movable tail stock that mounts on a linear slide, which applies force at the right angle to the axis of rotation.

5. Torsional Stiffness Testing Machine:

A Torsional Stiffness Testing Machine is useful in determining the torsional stiffness of a particular material. It can be a plate, beam, or bar.

The machine applies a sinusoidal load to the specimen and measures the rotation of the model using an LVDT attached to the sample.

It is helpful to find the shear modulus of elasticity and determine failure pressures and strains.

It is used in the engineering and metallurgy industries to subject materials to torsion. Such a machine can be classified as either an instrumented torsional test system or an un-instrumented testing machine.

6. Old Vertical Torsion Testing Machine:

An old vertical torsion testing machine is a device that measures a material’s shear modulus and damping.

It determines the modulus of elasticity and other mechanical properties of a material by applying a force along its axis and measuring the resulting torque.

The sample undergoes vertical oscillations at specified angular acceleration. It applies to the detection and quality control of the wire rope.

It is an important machine to determine how fast the materials get damaged by mechanical vibration, which helps design products with better endurance.

7. Axial-Torsion Testing Machine:

Axial-torsion testing machine is a test machine for the torsional properties of shafts and other round parts.

It is used to measure the torque required to cause torsional deformation (twisting) of a specific area of a material.

It applies both torque and axial load (also known as axial force). The specimen can be one of many different shapes, such as round, square, triangular, rectangular, etc.

It does this by exerting a known force upon the sample and measuring the maximum amount of deformation (if any) that occurs before failure.

8. Optical Fiber Torsion Testing Machine:

An optical fiber torsion testing machine is a helpful device for measuring the mechanical properties of an optical fiber.

It is a valuable tool to test the performance of fibers during construction and after installation.

It performs torsional tests on fiber optic cable under tension and temperature. The machine applies a specific amount of torsion to the test sample and measures the changes in attenuation of light propagating through it.

It allows you to test the mechanical properties of an optical fiber, which can help decide the best components to use when assembling a cable or designing a cable. The instrument is widely helpful in the production, maintenance, and quality control of optical fibers to ensure that they can satisfy their transmission requirements.

9. Wire Torsion Testing Machine:

A wire torsion testing machine helps to determine the strength and elasticity of wire. The device measures the torque required to twist an object as a function of angular displacement under controlled conditions.

It measures the amount of twist imparted to a sample under controlled conditions as a function of applied torque.

It is also helpful in determining the amount of twisting strain that a wire can withstand without breaking.

It allows for precise measurement of the torque needed to turn a nut or bolt without imparting any other stresses to the material being tested.

It is used in physics experiments and resists by twisting the wire and measuring its breaking force and used in industrial research and development for materials characterization and product testing.

10. Analog Torsion Testing Machine:

An analog torsion testing machine tests the material stress-strain response of manufactured products.

The product under test is loaded with an increasing load until failure occurs and the output is recorded as a function of applied force, displacement, or time.

An analog torsion testing machine is the most commonly helpful torsion testing machine.

It has high accuracy, easy to use, and has fast test results. Analog torsion testing machine comes with a high-precision potentiometer system that one can set to any angle for measuring and controlling torsion.

You can use this machine primarily to produce torque wrenches and indicators.

11. Cement Tensile Torsion Testing Machine:

A cement tensile torsion testing machine is a kind of special equipment used for cement samples torque tests.

It has high accuracy, strength, and flexibility. The construction engineering site can use it to make the quality inspection of concrete mixers and the power of building materials, such as concrete and mortar cement plant products.

It tests the breaking strength and material elongation of the concrete. It measures the physical properties of high-performance concrete (HPC), such as compressive strength, flexural strength, modulus of elasticity, and many more.

Read also: Cochran Boiler: Application, Working, Main Parts & Advantages

Torsion Testing Machine Price:

As we already know, there are numerous types of torsion testing machines. The torsion testing machine price differs on the kind of machine, features, label, and other factors.

The average price range of a Torsion Testing Machine is around INR 75000 to INR 1.85 lakhs, varying from one brand to another.

For a horizontal torsion testing machine for college purposes the price range is around INR 35,000 to INR 2 lakhs as per the brand and specification of the product.

Torsion Testing Machine Pdf

Know more about the Torsion testing apparatus from our Pdf files:

Least Count of Torsion Testing Machine:

Let us know about it before dealing with the least count of a torsion testing machine. The least count of torsion testing machines is the least number of turns it gives to a sample to produce an elastic limit, based on the material and the stress applied.

The least amount of torsion a testing machine can test is 0.006-0.06 Nm.

It depends on the device, which differs from model to model so the least count may vary.

Conclusion:

It is not an easy task to find a device that fulfills all your requirements and fits your budget.

But Tesca Global can help you in doing so, i.e., getting a high-quality torsion testing machine that fits your budget.

Tesca Global Pvt. Ltd. deals in torsion testing machines.

We provide a wide range of Torsion testing machines in the industry. Our machines are made using high-grade components and are energy efficient.

Tesca Global offers a varied range of torsion testing machines as per the customer’s needs and specifications of torsion testing machines.

The various types of torsion testing machines included in their products are universal, manual, digital, etc.

- Tesca Global specializes in providing a wide range of torsion testing machines for quality inspection and certification.

- The machines are suitable for various applications such as medical devices, aerospace, defense, automotive and industrial uses.

- With these machines, users can perform torsional load tests on their products and analyze the material performance or condition of materials under torsional load.

Although there are numerous types of torsion testing machines available in the market, it is good to consider looking for effective ones by choosing a reliable manufacturing company.

If you are looking for a reliable manufacturer of Torsion testing machines, Tesca Global is a worth mentioning name in the top names in the industry. Scroll through the website of Tesca to find a high-graded device that fits your budget now!

Faqs:

What is the Torsion Testing Machine Sample Rate?

The sample rate depends upon the type of device. The average sample rate testing machine is 0.006-0.06 Nm. It depends on the device, which differs from model to model, so it’s tough to say exactly how many turns it needs at any given moment to meet your desired outcome or output requirement based on what role you play. For example, it can range from 2 to 10 Nm (18 to 90 in-lb) and sometimes, depending on what capacity the device has, as mentioned before, a higher number is possible as well.

What is the price of a Torsion Testing Machine Nm 10000?

There are many types of torsion testing machines available in the market, and the costs vary depending on the kind of machine, characteristics, label names and other factors.

For a good quality torsion testing machine, in particular nm 10000, the average price is between 50,000 INR to 5 lakhs INR as per the machine’s specification.

Add comment